Basic HTML Version

308

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

Experimental analysis of reinforced concrete columns strengthened with self-compacting concrete

and connectors

shape of a “c” 140 mm wide, 35 mm high and a 70 mm extension.

Once fixed and involving the stirrups of the columns, they allowed

a 25 mm coating.

Figure 7 shows the location of connectors on the compressed face

of each column. They are represented by an ongoing line and also

show the thickness of the furrows and the distance between them.

Furrowing was needed to uncover shear reinforcement, thus en-

abling the connectors to be tied to the stirrups. The 110 mmwide

furrows were accomplished with the use of electrical demolition

hammer, manual hammer and metal pointer. With the stirrups in

place (Figure 8), the concrete surface was cleaned and the sub-

strate was wet in order to present a saturated dry surface. Struc-

tural adhesives were not used for bonding the substrate and the

strengthening concrete. Substrate scarification was carried out by

spraying only sand all over the compressed face of all the strength-

ened columns.

To the strengthening the columns, SCC was prepared to achieve

an average compression strength of 30 MPa at 28 days. Table 1

shows the proportion of materials used to produce a cubic meter

of concrete.

With regard to the slump flow test, the EFNARC (2002) recom-

mends that slump floow values ought to range from 650 to 800

mm. The concrete used to strengthen the columns showed slump

flow values of 760 and 750 mm for the first and second castings,

respectively (Figure 9). According to EFNARC (2002), the L-Box

test should have a h

2

/h

1

relation (height that concrete reaches

at the edge of the L-box/height that concrete maintains at the

beginning of the L-box) equal to 0.80. Dosed concrete revealed

values ranging from 0.81 to 0.84 (first and second castings, re-

spectively). Gomes et al. (2003) show Lt

20

values (reading of the

time concrete takes to reach a 20 cm marking on the L-box) rang-

ing from 0.5 to 1.5 seconds and Lt

40

values (reading of the time

concrete takes to reach a 40 cm marking on the L-box) ranging

from 2 to 3 seconds. The first casting revealed Lt

20

= 1 second

and Lt

40

= 2.5 seconds, whereas the second casting marked Lt

20

= 1 second and Lt

40

= 3 seconds.

Regarding the V-Funnel 5 min, EFNARC (2002) establishes a limit

ranging from 6 to 12 seconds and a difference between the first

and the second assays lower or equal to 3 seconds. The first cast-

cal to P6 and was made after a power outage had occurred in the

laboratory while performing tests on column P6.

Columns were cast horizontally and the tracing was dosed to

achieve an average compressive strength value of 30 MPa at

28 days. The conventional concrete used was pumped from the

concrete mixer to steel forms and mechanically compacted by an

immersion vibrator (25 mm diameter). During casting, 36 cylindri-

cal test samples measuring 150 mm x 300 mm were molded for

concrete characterization. Tests assessed compression strength,

tension by diametral compression and elasticity modulus. The col-

umns and the test samples were submitted daily to wet curing and

were covered with plastic canvas for seven days. After the seventh

day, the columns were removed from the mould and placed in the

laboratory until the date of the tests.

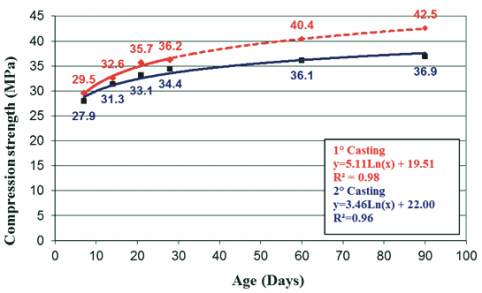

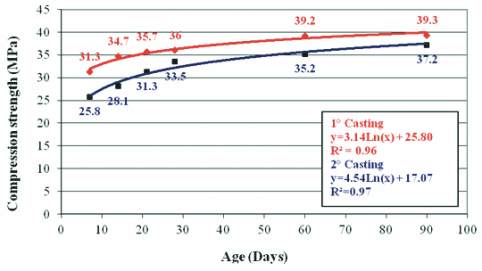

Figures 5 and 6 show the increase of the compressive strength of

concrete with the age of conventional concrete used in substratum

and the SCC used in reinforcement respectively.

The connectors were made from 5 mm diameter steel bars taken

from the same steel batch used for the stirrups of the columns

(Figure 5). With a total length of 350 mm, the bars were bent in the

Figure 4 – Stress-deformations curves

of 10 mm steel bars

Figure 6 – Concrete compression

strength of SCC with age curves

Figure 5 – Compression strength of substrate

concrete with age curves