Basic HTML Version

310

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

Experimental analysis of reinforced concrete columns strengthened with self-compacting concrete

and connectors

ing revealed 8 and 11 seconds for the first and second tests, re-

spectively, whereas the second casting revealed 7 and 10 seconds

for the first and second tests, respectively. The test arrangements

consists of a metal porch anchored by tie bars connected to the

strong slab. Figure 10 displays the arrangements of the test sys-

tem used.

3. Results

This topic presents and analyses the main results obtained from

tests and is divided into three sections: loads and failure modes,

horizontal displacements of the columns and finally the strains

measured in reinforcements and on the concrete’s face.

a) Load and failure mode

The original reference column P1 failed at 140 kN by steel yielding,

whereas monolithic reference column P2 failed at 450 kN by con-

crete crushing. The remaining columns failed by concrete uncoat-

ing, except column P8, which showed concrete crushing. Strength-

ened columns P6 and P6A showed greater concrete strain than

concrete crushing (3.5 mm/m - NBR and 3.0 mm/m - ACI), but af-

ter uncoating. Table 2 shows failure loads, strengths and elasticity

moduli of both substrate and strengthening concretes on the assay

dates of each model, initial and final eccentricities, maximum steel

and concrete strains and failure modes of each column. Strength

values of conventional and self-compacting concretes averaged

10% and 25%, respectively; they were higher for columns P1 to P6

than for columns P6A, P7 and P8. Figure 11 shows the location of

the failure in each tested column.

The monolithic column P2 (155 mm x 250 mm) failed with a 450 kN

load. This column was built to represent the maximum load capac-

ity possible that reinforced columns could reach. The P8 column

reinforced with the highest failure load, failed with a load 16% (Pu

= 520 kN) greater than that of P2. A likely and possible small dif-

ference in initial eccentricity could be one reason for the decrease

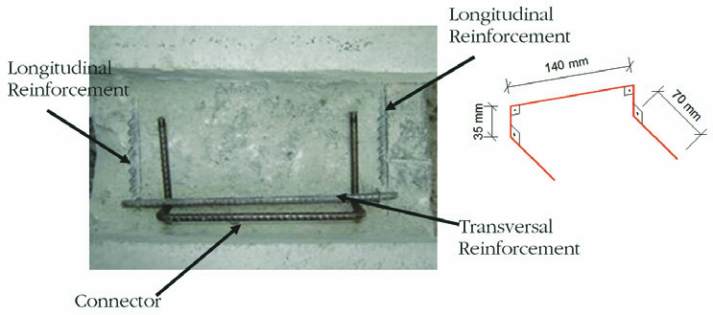

Figure 8 – Placement of reinforcement connectors

3

Table 1 – Proportion of substrate materials per m of concrete

Materials

Substrate

Strengthening Concrete (SCC)

3

Quantity (p/m )

3

Quantity (p/m )

Cement

310 kg

360 kg

Natural Fine – Coarse Sand

155 kg - 233 kg

730 kg - 0 kg

Artificial Sand

497 kg

-

Silica

-

31 kg

Grit 0 – 1

388 kg - 619 kg

930 kg - 0 kg

Water

155 l

223 l

Superplasticizer

-

-

3.96 kg (1.1% on cement)

Set Retarder Additive

2.17 l

2.88 kg (0.8% on cement)

Slump (95 ± 10) mm

Flow test = 700 mm