Basic HTML Version

346

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

Post-strengthening of reinforced concrete beams with prestressed CFRP strips.

Part 1: Analysis under static loading.

This process is repeated in several stages until the entire length of

the strip is bonded and the prestressed level at the ends of the strips

has been reduced to a low level, as one can see in Figure [4]. In this

way, anchorages are not required at the end of the prestressed strip.

In the prestressing method developed by Stoecklin and Meier [12]

the strip is prestressed before the application at the beam. In such

case, prestressing is applied by reacting against the structural

member, since the prestressing device is mounted to the structure.

When the first FRP strip is prestressed, using the device developed

by Stoecklin and Meier [12], imediate losses of prestress due to elas-

tic deformation of the concrete, that happen when the prestress force

is released, can be neglected, since prestressing is applied by react-

ing against the structural member. However, strips that have already

been prestressed will experience a loss of prestress due to the short-

ening of the beam upon the prestressing of subsequent FRP strips.

2.4 Failure Modes of reinforced concrete beams

post-strengthened with prestressed FRP,

submitted to static loading

According to Hollaway [14], the anisotropic behavior of the com-

posite materials leads to a complex rupture mechanism that may

be characterized by extensive damages on the composite material

when submitted to static and cyclic loading. The level of damage,

however, depends on the properties of the composite material and

on the applied loading.

Failure modes of reinforced concrete structures post-strengthened

with FRP include crushing of concrete, yielding of steel reinforce-

ment or tensile failure at the FRP.

Teng et al. [15] report that failure modes of reinforced concrete

beams post-strengthened with FRP can be broadly classified into

two types: those associated with high interfacial stresses near the

ends of the bonded FRP and those induced by a flexural or flex-

ural-shear crack away from the ends, which is also referred to as

intermediate crack-induced debonding. Thus premature failures, in

general, are associated to:

n

High interfacial stresses near to the ends of the bonded FRP,

also called peeling-off.

n

Flexural or flexural-shear crack away from the ends, as shown

in Figure [5].

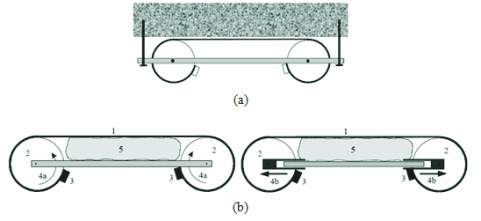

prestressing device consists of two wheels which are connected to

a beam of the required length, as shown Figure [02] (a).

The FRP strip (1) is wrapped around the wheels (2) and clamped at its

ends (3) as shown in Figure [2] (b). The strip can be prestressed by ro-

tating one or both wheels (4a) or displace the wheels (4b). As one can

see in Figura [02] (a), the prestressing device with the prestressed FRP

strip is temporarily mounted to the structure and can be pressed against

the structure with a constant pressure by means of an air-cushion (5)

between the FRP strip and the beam. (Stoecklin e Meier [12]).

In a new version of the prestressing device developed by Stoecklin

and Meier [12], two separate prestressing units at each end of the

strip are directly mounted to the structure, what means that the FRP

strip is prestressed against the structure, as shown in Figure [3].

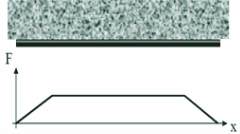

To overcome anchorage problems at the ends of the FRP strips,

the prestressing force can be reduced gradually from the mid-span

to both ends of the FRP strips.

As described by Meier et al. [13], gradual anchoring is achieved

by first bonding a fully pretensioned section in the middle of the

FRP strip at mid-span. A system of electric heating may be used to

speed up curing of the adhesive in the bonded section within the

pot life of the adhesive. After curing the central part of the FRP strip

at mid-span, the prestressing force is slightly reduced and another

section is bonded at each side of the strip also using the electric

heating system to speed up curing the adhesive.

Figure 2 – Prestressing device developed

by Stoecklin & Meier [12]: (a) Placement

of the prestressing device under the beam;

(b) Two ways of prestressing a CFRP strip

A

B

Figure 3 – New version of the prestressing

device develloped by Stoecklin & Meier [12]

Figure 4 – Gradual anchorage of prestressed

CFRP strips [Stoecklin & Meier [12]]