Basic HTML Version

1. Introduction

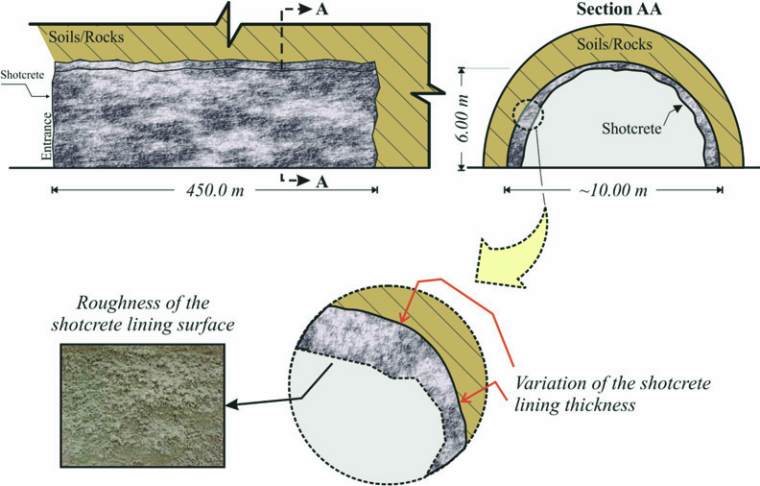

The use of shotcrete in tunnel linings is common practice. How-

ever, correct measuring and projection techniques are not always

employed. An example of a shotcrete structure that has demon-

strated non-compliance with the mechanical properties of the con-

crete was the water intake tunnel lining of a small hydroelectric

plant (SHP) located at Santa Rosa de Lima, SC, Brazil.

In this structure, which is presented in Figure 1, part of the con-

crete lining began displaying structural problems three weeks after

the application of shotcrete onto the tunnel wall. These problems

might have been originated from the projection process and/or the

measuring process of the materials in the shotcrete. Therefore,

this study was performed with the initial goal of defining a method-

ology for the evaluation of shotcrete structures and then evaluating

the compressive strength of the tunnel lining to verify the applica-

bility and effectiveness of the proposed method.

Initially, the extraction of samples was considered as a method to

determine the compressive strength of the concrete used in the

tunnel. Nevertheless, this option was discarded because of the in-

clination of the tunnel walls, the variation in the thickness of the

concrete lining layer (detailed in Figure 1), and the high cost of

sample extraction. Thus, the possibility of using a non-destructive

test was considered. The proper type of non-destructive test had to

be chosen based on the structure characteristics.

2. Non-destructive tests used to assess

the structure

Several non-destructive tests are applicable in the evaluation of

concrete structures, [1,2], including the pullout test, the probe

penetration test, the maturity method, the rebound hammer test,

ultrasound, and impact-echo. In the present study, the reflection

rebound hammer test, the pin pullout test, and the probe penetra-

tion test were considered. These measurements are related to

technical, economic, and practical issues that will be discussed

throughout this section.

The use of a rebound hammer test was the first test possibility to

be considered due to its simplicity and low cost. This test is based

on the evaluation of a mass rebound after being fired against a

surface at a standard energy. The rebound hammer test is widely

used in evaluating finished structures. Examples of applications of

this test are presented in [3], where the rebound hammer test is

used to estimate the strength of reinforced concrete structures, and

in [4], where the same test is considered as suitable for evaluating

the uniformity of concrete structures. Regarding the assessment of

tunnels, Bilgin et al., [5], presents a practical application of this test.

However, the study is intended to evaluate the surface hardness of

rocks with the intention of providing the energy required for blast-

ing. The test could have been used in the assessment of the tunnel

in question if the surface lining was regular.

The results of the rebound hammer test are affected by a number

of factors, including I) the moisture conditions of the concrete sur-

face, II) the presence of a surface layer of carbonated concrete,

and III) the direction of the instrument, [6]. These factors, along with

the construction characteristics of the tunnel, are mainly due to in-

creases in the surface roughness and practically impede the use

of reflection sclerometry for the assessment of shotcrete structures.

The use of a pullout test was also considered for the evaluation

of the structure in question. The principle of this test is to mea-

sure the shear stress required to pull out a pin that is embedded

363

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

W. R. L. da Silva | L. R. Prudencio Jr

|

A. L. de Oliveira

Figure 1 – Schematic details of the tunnel