Basic HTML Version

507

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 4

B. F. TUTIKIAN | M. PACHECO

Following the completion of the compactness test, the next step

was to determine the water/cement ratio and the amount of super-

plasticizer admixture.

From that point on, unit composition I (1:4) was used to prepare

the adjustment mixture, so as to confirm the water/cement ratio

and, most importantly, determine the amount of superplasticizer

admixture experimentally. First an admixture value of 0.50% (con-

sidering the amount of solids and liquids in the admixture) was

defined, in relation to the cement mass and a water/cement ratio of

0.40. After determining those values, the intermediate mixture was

initiated, and from the tests performed in the fresh state, the final

ideal amount of superplasticizer admixture and the water/cement

ratio were defined.

From the results obtained, the final unit compositions for the SCCs

were determined without the need for substitutions. According to

the method, the ideal is to create four points so that the behavior

equations have a higher coefficient of determination, allowing the

curves to be better adjusted. The individual unit compositions are

shown in Table 1.

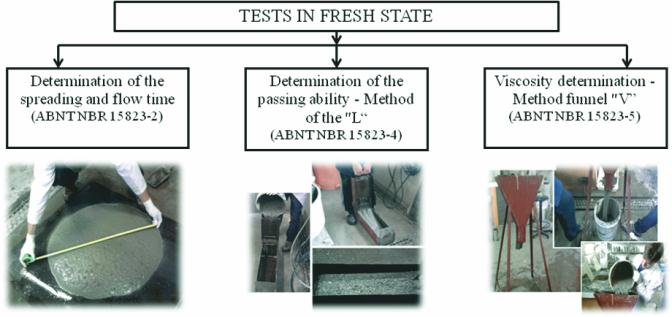

3.2 Tests performed in the fresh state

In the fresh state the SCC families were tested in order to assess

the flow properties, passing ability, resistance to segregation and

apparent plastic viscosity, following the technical specifications de-

fined by ABNT NBR 15823:2010 [4]. The tests included flow tests

(SF), draining time (VS), “L-box” (PL) and “V-funnel” (VF). Fig. 5

shows the tests in the fresh state being performed in the lab.

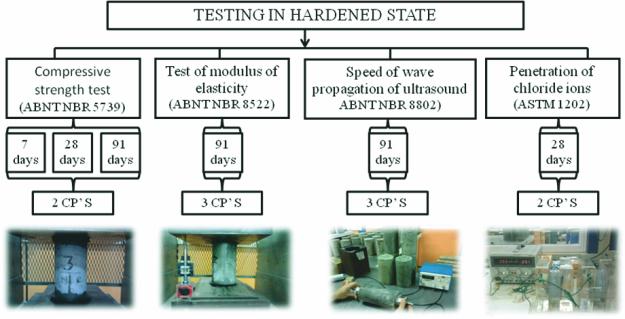

3.3 Tests performed in the hardened state

In order to compare the properties obtained in each SCC family in

the hardened state, the concretes were submitted to compressive

strength tests at 7, 28 and 91 days, modulus of elasticity at 91

days, propagation velocity of the ultrasound wave at 91 days, and

chloride ion penetration at 28 days.

The compressive strength test, performed in compliance with ABNT

NBR 5739:2007 [7], was carried out because that is the most com-

monly used property in research and in real applications, as well as the

Figure 5 – Tests carried out in the fresh state

Figure 6 – Tests carried out in the hardened state