Basic HTML Version

660

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

Punching strength of reinforced concrete flat slabs without shear reinforcement

1. Introduction

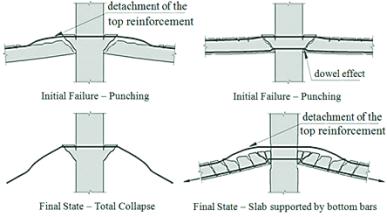

Flat slabs are those which are directly supported on columns wi-

thout capitals. They can be considered as a good option for con-

crete buildings since they may reduce the construction time due to

the simplification of forms and rebars and especially by attributing

greater flexibility in layout of floors. The design of slab-column con-

nection is the most critical point in the design of flat slabs, because

of the concentration of shear stresses in this region that can lead

to punching, which is a localized failure mode that can occur wi-

thout significant warnings and may lead the whole structure to ruin

through the progressive collapse. Figure 1a shows an example of

punching failure recorded by Ferreira [1]. One way to ensure local

ductility and prevent progressive collapse of flat slabs is through

the use of post-punching reinforcement as those shown in Figure

1b, which must be designed to carry the vertical reaction in the

column, and must be detailed in order to ensure that they are suffi-

ciently anchored beyond the region of the possible punching cone.

Since tests carried by Elstner and Hognestad [2] many other stu-

dies have been conducted aiming to understand the behavior and

strength of flat slabs. Some theoretical methods were proposed

but none was generally accepted because they were not able to

accurately estimate the punching resistance of slab-column con-

nections and at the same time explains the phenomenon with all its

variables. Thus, the design of flat slabs to the punching is normally

done using recommendations presented by codes of practice for

design of concrete structures, which are essentially empirical.

Recently Muttoni [3] presented a new theoretical approach called Cri-

tical Shear Crack Theory (CSCT), which is able not only of predicting

the bearing capacity of slab-column connection, but also of estimating

their behavior in service (rotation, displacements and strains). This the-

ory is based on the idea that the punching resistance decreases with

increasing rotation of the slab, and has recently been embodied in the

first draft of the new fib Model Code [4,5], which was presented in 2010,

and has come to replace the old CEB-FIP MC90 [6]. This paper aims

to evaluate this method by comparing its theoretical results with experi-

mental results of tests of 74 reinforced concrete flat slabs without shear

reinforcement carefully selected (see section 6 of article) to form a lar-

ge database, with specimens with a significant variation of parameters

such as the effective depth, flexural reinforcement ratio and compressi-

ve strength of concrete. These experimental results were also compa-

red with the theoretical results obtained by using the recommendations

of ACI 318 [7], EUROCODE 2 [8] and NBR 6118 [9].

2. Historical development of flat slabs

There is controversy about who idealized the flat slabs structural

system. Gasparini [10] states that the credit for the development of

this system should be given to George M. Hill, an engineer who re-

portedly designed and built constructions like filtration plants and

storehouses in different regions of the United States between 1899

and 1901. He emphasizes, however, that C A. P. Turner, an Ameri-

can inventor and engineer, was the one responsible for demonstra-

ting that these slabs were reliable with numerous buildings construc-

ted, the first being Johnson-Bovey building in the city of Minneapolis

in 1906. Turner’s “mushroom” slab were characterized by the pre-

sence of capitals in the slab-column connection and also by the use

a cage comprising bars of 32 mm diameter, working as shearheads.

Furst and Marti [11] attributed the invention of this system to the

Swiss engineer Robert Maillart, most famous for his works with

bridges than the development of such structural system. According

to these researchers, Maillart would have designed the system in

1900, but had only completed his tests in 1908, coming to get the

patent of the system in 1909. Kierdorf [12] points out that while

the system was developed independently in the United States and

Switzerland, with the prohibition of the use of reinforced concre-

te in Russia in 1905, the engineer Arthur F. Loleit designed and

implemented a factory nearby at the Moscow in 1907 in flat sla-

bs, have been the first of several buildings in slabs without beams

made by him in Russia. The author further comments that if his

presentations of “beamless” construction at the regular meeting of

cement specialists in Moscow (1912) and to the Russian Society

for Materials Research (1913) had been documented, and also if

WWI (1914-1918) had not happened, Loleit would certainly have

presented his work to a broader public. Some details on the deve-

lopment of flat slabs can be seen in Figure 2.

Figure 1 � Punching shear failure in slabs without shear reinforcement (Ferreira [1])

Punching shear failure

Without

post-punching

reinforcement

With

post-punching

reinforcement

A

B

C