Basic HTML Version

705

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

E. RIZZATTI | H. R. ROMAN

|

G. MOHAMAD | E.Y. NAKANISHI

3. Factors that influence

masonry strength

The main material responsible for the strength of masonry is the

block. There are some Brazilian studies on the mechanical be-

haviour of clay masonry [7 and 8]. In these studies, the blocks

have different geometries, and in most cases, the results cannot

be compared in terms of mechanical efficiency due to different as-

pects such as the heterogeneous nature of the mixture, fineness

of the clay, hole format and the firing temperature. Furthermore,

in Brazil there have been few experiments using small-scale mod-

els as a means of interpreting mechanical and physical phenom-

enon. Thus, it is important to conduct technical studies on material

behaviour to support the technical decisions for developing new

structural products.

3.1 The block influence on masonry strength

Clay blocks are structural masonry components with prismatic or

circular hollows aligned in the direction of the load application,

so that the block is set with the hollows oriented vertically. Bed-

ding clay blocks are classified as follows: either (a) structural clay

tion between the prism and block strength was affected by the

scale factor with a value of 0.4, 0.5 and 0.6 for small scales of

1:1, 1:3 and 1:5, respectively. Although there were differences

in the strength results, the failure mode presented by the pro-

totype and the small-scale models were similar. CAMACHO

concludes that it is possible to use small-scale models to de-

termine the behaviour of clay block masonry.

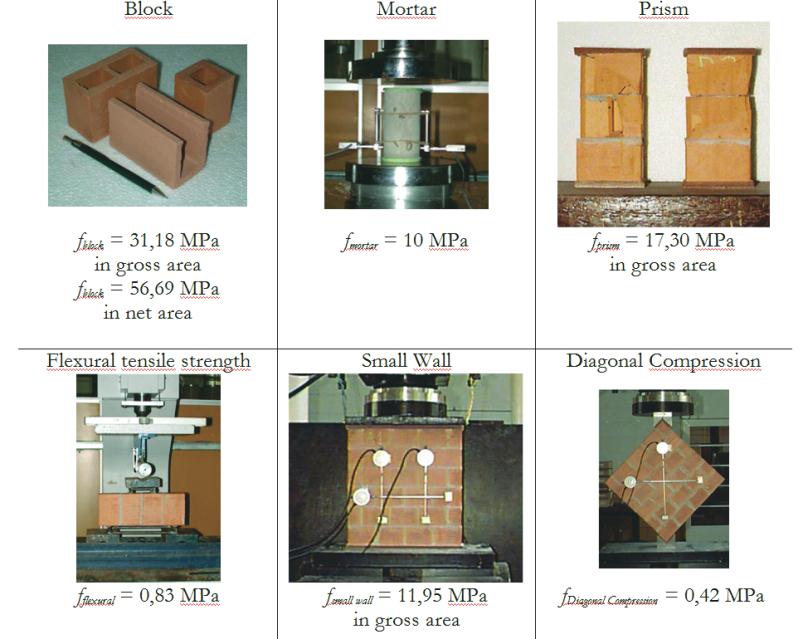

NETO [6] studied theoretical and experimental behaviour of ma-

sonry walls with openings, using small-scale models of 1:3. The au-

thor determined the mechanical behaviour of the components and

elements. The studies used structural clay blocks with two rectan-

gular hollows. The thickness of face shells and cross webs was the

same, and the relation between the net area and gross area was

55%. The dimensions of the units were 9.82 cm x 6.59 cm x 4.65

cm (length x height x width). Table 01 presents the experimental

test results and the corresponding strengths. The failure modes of

prisms and small walls presented by NETO [6] showed crushing

of the bending mortar joint combined with a splitting displacement

at the contact point with mortar, with tensile cracks induced by the

application of compression stress. Combined with the compressive

strength results for prisms and blocks, it was possible to obtain the

efficiency factors of experimental tests of NETO [6], whose values

were

f

p

/

f

b

= 0.55 MPa and

f

small walls

/

f

b

= 0.38 MPa.

Ta�le � � ��pe�imental �esults of the components and elements of Nascimento (2003)