Basic HTML Version

708

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

Mechanical behavior analysis of small-scale modeling of ceramic block masonry structures –

Geometries effect

webs of the blocks. The authors noted that there were no changes

in the ratios between net and gross areas of the blocks.

The results showed that blocks with three vertical hollows pro-

duced higher levels of stress than blocks with two vertical hollows.

The stress level remained constant in the region close to the centre

of the prism. Regarding the cross webs, the difference in behav-

iour among the three types of blocks was more evident for running

bond prisms. As a conclusion of the work of GANESAN and RA-

MAMURTHY [11] on the mechanical behaviour of masonry, it can

be verified that the geometry of the block influenced the distribution

and the magnitude of the stress level. Moreover, mortar did not

influence the behaviour of masonry and stack bond prisms overes-

timated the masonry strength. Another important conclusion was

that the ratio of the compressive strength of walls to that of blocks

depended on the block geometry and the type of laying mortar.

The authors found that for some geometries and mortar, there

are stress concentrations that reduce the compression strength of

masonry. Figure 07 shows the geometries and the compressive

strength of blocks and walls along with efficiency factors. For Type-

A blocks the mortar was applied only on the faces shells while for

others the mortar was applied on the entire surface of the block.

3.3 The mortar influence on masonry strength

Development of units (blocks) with greater compression capacities

requires a proportional strength increase in the mortar joint, due to

a failure mechanism of masonry that is closely related to interaction

among these components, as it is shown in Figure 08. Several stud-

ies were carried out in Brazil to determine the influence of mortar,

in which the studies carried out by GOMES [7] stand out. GOMES

concludes that mortar strength should be between 0.7 to 1.0 times

the block strength measured over the gross area. GOMES state that

when mortars with a compression strength close to that of the block

are used, the masonry will display an excessively fragile failure with

subsequent instability of the structure. MENDES [8] also conducted

studies on hollow clay block prisms that were 140 mm wide x 290

mm long x 190 mm high (shape of Figure 05-b), where the relation-

ship between the net and gross areas was 0.52. Experiments were

conducted on grouted and non-grouted prisms with two compres-

sion strengths of mortar. Based on the studies of MENDES [8], it

can be observed that failure of non-grouted prisms is due to the

crushing of mortar joints generating tensile concentrations in the

blocks and splitting the contact surface between the block and mor-

tar. The failure types of non-grouted prisms were fragile for prisms

with mortar A1 and the crushing of the block lateral walls for mortar

A3. For grouted prisms, all walls of the block (face shell and cross

webs) were separated. The separation was caused by the lateral ex-

pansion of the grout creating tensile concentrations that separated

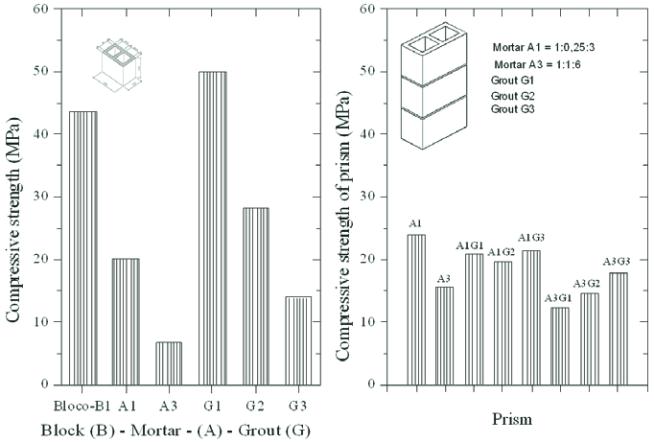

the face shell and the cross webs. Figure 09 presents the individual

results for the block (B1), mortars (A1 and A3), grouts (G1, G2 and

G3) and the different strength combinations between non-grouted

and grouted prisms. The failure modes of grouted and non-grouted

prisms are presented in Figure 10, as well as block geometry and

the failure process for grouted prisms. Regarding the recommenda-

tions of BSI-5628-1 [10] in Figure 06 and the experimental results

of GOMES [7] and MENDES [8], it can be concluded that mortar

strength did not significantly influence the compressive strength of

masonry for block strengths from 2.5 to 10 MPa. However, for blocks

with compressive strength greater than 10 MPa it was verified that

the mortar influenced the compressive strength of masonry.

4. Experimental Program

An experimental program was carried out with prepared clay unit

blocks and masonry components using small-scale models with

proportions of 1:3.

Figure � � �esults of compressive strength of the block, mortar, grout and prisms (MENDES [8])