Basic HTML Version

714

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

Mechanical behavior analysis of small-scale modeling of ceramic block masonry structures –

Geometries effect

T�ble � � Res�lts of compression strength of prisms

Block

Prism

Type

PRISM

PRISM

PRISM

MORTAR I

MORTAR II

MORTAR I

f A

net.

f A

gross

f /f

p b

f A

net.

f A

gross

f /f

p b

f A

net.

f A

gross

f /f

p b

f

p

f

p

f

p

20,48

10,56

0,36

24,50

12,64

0,43

24,27

12,52

0,43

A

s.d

s.d

s.d

2,10

4,30

1,29

c.v

c.v

c.v

10,30

17,57

5,32

f

p

f

p

f

p

23,64

13,61

0,42

26,59

15,31

0,47

25,98

14,96

0,46

B

s.d

s.d

s.d

2,05

2,83

1,03

c.v

c.v

c.v

8,67

10,65

3,96

f

p

f

p

f

p

23,04

11,18

0,37

26,03

12,64

0,41

28,59

13,88

0,45

C

s.d

s.d

s.d

3,98

0,96

4,30

c.v

c.v

c.v

17,30

7,61

15,00

f

p

f

p

f

p

20,30

11,67

0,35

22,99

13,22

0,39

26,25

14,88

0,45

D s.d

s.d

s.d

1,42

1,74

3,34

c.v

c.v

c.v

7,00

7,56

12,70

Where: f is the prism strength (MPa); f /f is efficiency factor between prism strength in relation to the block; s.d. is the standard

p

p b

deviation (MPa); c.v is the coeficiente of variation (%); f A is the strength in the net area; f A is the strength in the gross area.

net

gross

The experimental results of compression tests of stack and run-

ning bond prisms with mortar types I and II are presented in Table

08 along with the standard deviations and coefficients of variation.

The compressive strength results for prisms and blocks were ob-

tained

for both the net and gross areas (ES 772-1 [18]). There

were no significant differences in the compressive strength results

for prisms using the different block types A, B, C and D. The small

differences in the strength values are likely due to the superposi-

tion of the face-shell and the cross webs of the blocks for the two

types of prisms. Table 08 presents the efficiency factor between

the compressive strength of prisms and blocks (

f

p

/f

b

). It was ob-

served that there was a reduction in the compressive strength be-

tween prisms and blocks of approximately 55% to 65%. The failure

mode of prisms were similar to those obtained by MENDES [8]

who observed a failure caused by crushing of the bedding mortar

joint and the splitting of the surfaces between blocks and mortar.

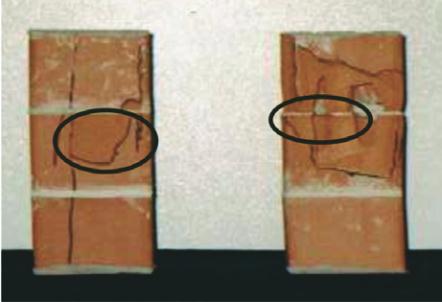

The circles in Figure 17 depict the failure modes of prisms. The

tests showed that scale-reduced prisms had failure modes similar

to those obtained for full-scale prisms.

For each type of block and mortar, three walls were built and test-

ed. The blocks were wetted before bedding so that water would

not be removed from the mortar, making it available to hydrate

the cement. The blocks at the top and bottom of the walls were

capped with the cement paste and sand mixture described above

before testing. Walls were tested 28 days after construction, and

remained in the laboratory environment between construction and

testing. Table 09 presents the compressive strength results for

walls with different block geometries and two types of mortar along

with the standard deviations and coefficients of variation measured

on both the net and gross areas. Figure 19 presents the individual

compressive strength results for blocks, mortars, prisms and walls.

Figure �� � F�ilure mode of

three-block prism