Basic HTML Version

716

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

Mechanical behavior analysis of small-scale modeling of ceramic block masonry structures –

Geometries effect

Figure 19 shows the values

of efficiency factors between the prisms

and walls relative to the blocks, where:

f

PA1/

f

B = compressive

strength of prism with mortar I divided by the compressive strength

of block;

f

PA2/

f

B = compressive strength of prism with mortar II di-

vided by the compressive strength of block;

f

PPA1/

f

B = compressive

strength of wall with mortar I divided by the compressive strength of

block;

f

PPA2/

f

B = compressive strength of wall with mortar II divided

by the compressive strength of block. Figure 19 also presents the ef-

ficiency factor of masonry walls, which are 1.00 when the compres-

sive strength of the wall is equal to that for clay blocks. The experi-

mental results showed that there was a significant reduction in the

Figure �� � �fficiency factor of prisms

and walls for the two mortar traces (I and II)

efficiency factor of prisms and walls with different clay blocks. For

the walls using the blocks of types A, B, C and D, the efficiency fac-

tors did not depend on the type of mortar (I and II). According to the

experimental results, the geometry of block D presented the best ef-

ficiency, close to 0.25. The improvement in the vertical distribution of

stress over the face shell and the cross web due to the geometry of

block D, where the longitudinal wall was twice as thick as the block’s

wall thickness plus the thickness of the mortar joint, increased the

compression efficiency of the masonry. No differences were found

for the compressive strength of prisms for different block geometries

either with or without the presence of half blocks at an intermediate

course. That is, the prisms failed to show influence of block geom-

etry. Thus, it is possible to conclude that the geometry of block D

presents a better compression performance compared to the others.

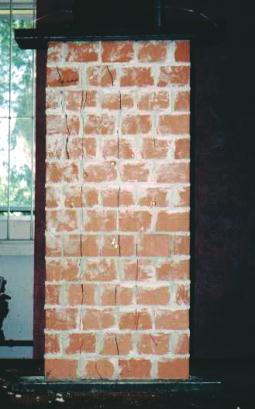

Figure 20 shows the failure mode under compression of walls built

with different types of blocks. No differences were observed in the

failure mode of walls with the block type. The cracks were basically

vertical with failure caused by the crushing of the bedding mortar

joint and splitting the surface of the block. The axial strain was mea-

sured with a mechanical extensometer, namely a “demec-gauge”

following the procedures of NBR 8522 [19], as shown in Figure 21.

The experimental results are the averages for three samples for

each type of block. The results led to the relationship between the

elasticity modulus and the compressive strength of masonry, the so-

called “

Ritter constant

” (k) for different block geometries as shown

in Equation (02).

(2)

E

wall

=

k. F

wall

Table 10 presents the average results of the elasticity modulus

of walls built with mortar type I. The elasticity was obtained at a

Figure �� � Failure mode of wall under compression