Basic HTML Version

605

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

V. J. FERRARI | J. B. DE HANAI

strengthening assists the steel to resist to tensile stresses. For the

beam V1C the increase was of 48.4%. In the beam V2C the in-

crease reached 67,1%.

Regarding the ultimate load it is highlighted the beam V2C re-

sponse. A significant increment of 120% was observed in relation

to the control beam, while the beam V1C presented a limited in-

crement of 65.1%. Considering the strengthened RC beam, the

resistance capacity for the beam V2C was 33.2% higher.

4.3 Vertical displacements

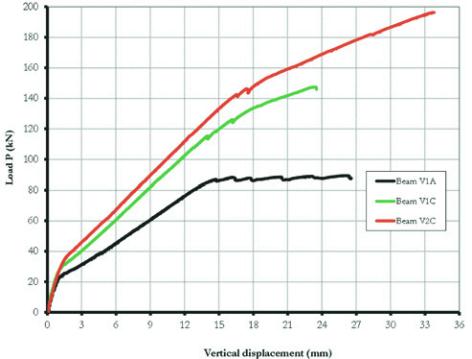

In the Figure [12] are compared, through the load-deflection

curves (P-d), the behaviors for the beams V1A, V1C and V2C. It

was observed that until the load cracking the response of beams

is similar. After the concrete cracking, it is clear the increase of

stiffness in the strengthened beams in relation to the beam without

strengthening. It is emphasized the effect of the transition layer in

the responses of the beam V2C. Higher stiffness and load capacity

were verified for this beam, especially in relation to the beam of

reinforced concrete V1C.

In the beam V1A it is observed that any addition of load after

the yield of longitudinal reinforcement was obtained. As for the

strengthened beams, it is clearly observed an increase of load

after the longitudinal reinforcement yield. In this way, the largest

extension for the final stretch of the curve of beam V2C indicates

that the strengthening was more required in this beam than in the

beam V1C.

In the Table [6] is presented a comparison between the deflection

for beams in the middle of span for a load equal to 90% of the

failure load of the beam V1A. The values show that the strength-

ened beams were stiffer than the control beam. The deflection

of the beam V1A was 47% larger than the deflection of the beam

V1C. The beam V2C presented a deflection even less pronounced

than the beam without strengthening. The displacement of beam

V1A was 67% higher than the beam V2C. Therefore, the innova-

tion proposed in the present paper, retrofitting and strengthening

of beam tensile zone, is not only effective in terms of load capacity,

but also in terms of stiffness.

4.4 Stresses and strains

The strengthening response is evaluated through the distribu-

tion of specific strain throughout its extension. Associating the

strengthening geometric and mechanical properties to values of

strain it is possible to obtain a distribution of longitudinal and tan-

gential stresses along the strengthening. It is possible to calculate

Table � � �oads and failure modes of the beams

Beams

P (kN)

f

P (kN)

y

P (kN)

u

Failure mode

Increments (%)

P

f

P

y

P

u

V1A

21.01

79.80

89.27

Excessive deformation for

the longitudinal

reinforcement

-

-

-

V1C

25.16

118.45

147.37

Strengthening debonding

19.8

48.4

65.1

V2C

34.92

133.37

196.35

Strengthening debonding

through the cement

composite interface

66.2

67.1

120.0

Figure 12 � ��ad�de��e�ti�n �ur�es ��

the beams V1A, V1C and V2C

Ta�le � � Comparati�e of �eams �eflections

Beams

Deflection (mm)

Comparison

V1A

12.79

1.00

V1C

8.73

1.47

V2C

7.68

1.67