Basic HTML Version

636

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

Fatigue lifetime of a RC bridge along the Carajás railroad

concrete in laboratorial tests, with a properly calibrated rebound

hammer is ± 15% 20%, and in a concrete structure is ± 25%.

The measurements of modulus of elasticity of the concrete (Ec)

determined experimentally according to NBR 8522 : 2003 [7],

are presented in Table 4 together with the resistance to axial

compression experimentally determined in accordance with

NBR 5739 : 1994 [8 ].

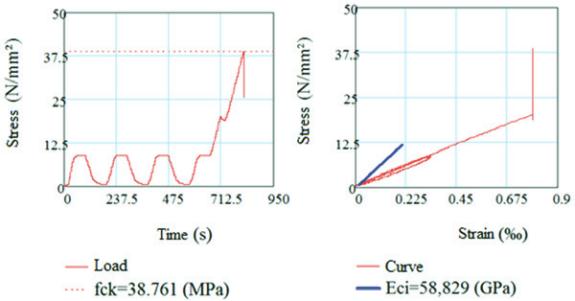

In Figures 16 to 20 it can be seen the result of the configura-

tion adopted for the tests as a function of time, where the loads

ranged from 0.5 MPa to 30% of the failure stresses estimat-

ed for the concrete testimonies according to the current code

prescriptions, and the stress-strain diagrams generated as the

tests were performed.

4. Structural project analysis according

to codes’ prescriptions

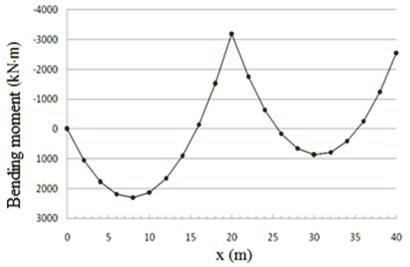

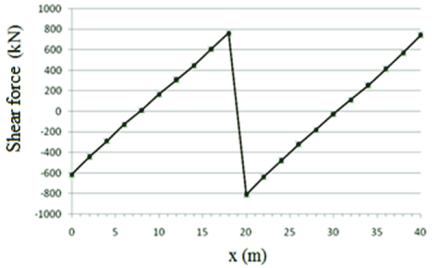

4.1 Dead load effects on the stringers

All permanent loads (corresponding to stringers self-weight,

Figure �� � �tress-time and stress-strain diagrams for the left side stringer

crossbeams, refuges, ballast, rails, accessories, etc.) and dy-

namic loads were separately considered, corresponding to the

several trains type studied (Cooper E80, operational, loaded,

future loaded and unloaded operational train-type). Figure 21

shows, respectively, bending moment and shear force diagrams

due to permanent loading from the computational program

SAP2000 [10].

4.2 Dynamic loads history

For the determination of the applied loading on the stringers (bend-

ing moment and shear) each of the spans was subdivided into ten

parts, resulting in 21 sections, as done in the calculation memory.

As illustration, the forces’ variation from SAP200 [10] for section

21 is presented, corresponding to the fix point between the deck

slab and abutment E2 and considered the most requested section

under several trains types passage without permanent loads. The

other sections time histories were also obtained, but only their en-

velopes are presented. Figures 22 to 25 show the dynamic loading

history for several trains.

Figure �� � �e��i�g ���e�t a�� shear ��rce characteristic values