Basic HTML Version

641

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

R. R. F. SANTOS | D. R. C. OLIVEIRA

possibility of extending the fatigue lifetime considering the current

value of concrete strength obtained from sclerometry and axial

compression tests on concrete testimonies.

6. Conclusions

After tests performed “in situ”, the taken concrete testimonies were

tested in laboratory and the results revealed that the concrete

compression strengths are much higher than those specified in the

project (18 MPa). Thus, the concrete of the current structure has

a degree of safety higher than that stipulated in the preparation of

structural design. The difference between the values for elasticity

modulus of concrete (referring to f

ck

stipulated in the project and

the result obtained in the tests) was also considered in the compu-

tational models to verify the bridge structure in relation to ultimate

limit states and serviceability limit states.

Based on direct observation of the state of the minerals, in the

investigation of the maintenance history, which directly reflects the

degree of reliability and integrity of the structure and of the theoreti-

cal models, it is concluded that at no studied point occurred cor-

rosion in the reinforcements nor CO

2

penetration into the concrete

layer corresponding to the coating. This indicates unfavorable con-

ditions for the advance of carbonation front provided by the envi-

ronment, giving a high reliability to the test results of sclerometry

which may be strongly affected by this phenomenon, once accord-

ing to the ACI 228R-89 (1989 ) [13] a carbonated surface layer

results in sclerometric indexes greater than those corresponding

to the inner layers of the structural element.

The sclerometry tests also revealed that resistance values do not

suffer large dispersions when comparing elements relatively dis-

tant along the structure, which reinforces the hypothesis concern-

ing “uniformity” in the strength of concrete. The pacometry tests

served to ensure compatibility between the existing and designed

reinforcements, but it is recommended to repeat the procedure on

a larger number of regions. The axial compression tests accord-

ing to NBR 5739 : 1994 and modulus of elasticity under the light

of NBR 8522 : 2003 converge with those obtained by sclerometry

and codes’ estimates, and the perceived differences are justified

by the different natures of the tests. The recommended values for

the strain corresponding to the maximum stress of concrete are

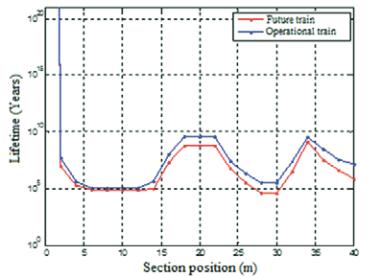

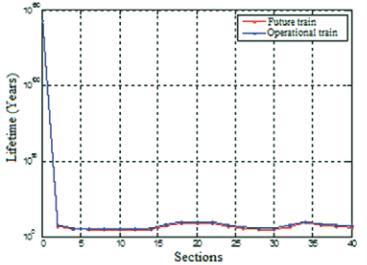

Figure �� � Fatigue lifetime analy�i� con�i�ering f from calculation memory

ck

also close to those observed experimentally. The characteristic

curve of the concrete, although atypical point modulus of elastic-

ity commensurate with analyzed codes’ estimates, however it is

recommended campaigns for removal of a greater number of con-

crete testimonies to increase the representation of the conclusions

related to the constitution of the bridge as a whole.

Regarding the fatigue results it was observed that the damage in

the elements of the cross section is low, except for the concrete of

the bottom surface of the section, which is very compressed due to

the concrete fibers are subject to considerable initial stresses (per-

manent loading) suffering large stress variations with the passage

of the moving loads. For the future loaded train, it was observed

that the element of greatest damage corresponded to the bottom

surface reinforcement and concrete of the studied cross section.

Because of this it is possible state that the OAE 50A shows no

fatigue problems.

7. Acknowledgements

The authors thank to company VALE, ITEGAM, FAPESPA and

CAPES for the financial support for this and other experimental

works carried out in Northern Brazil.

8. References

[01] CÁNOVAS, M. F. Pathology and therapy of the

reinforced concrete. São Paulo: Pini, 1998.

[02] CASCUDO, O. The control of reinforcement corrosion

in concrete: inspection and electrochemical

techniques. São Paulo: Pini, 1997.

[03] BRAZILIAN ASSOCIATION OF TECHNICAL

STANDARDS. NBR 6118: Design of concrete

structures. Rio de Janeiro, 1978.

[04] METHA, P. K. & MONTEIRO, P. J. M. Concrete:

microstructure, properties and materials. São Paulo:

Pini, 2008.

[05] EVANGELISTA, A. C. J. Concrete strength

evaluation using different non-destructive tests. (Ph.D.

Thesis). COPPE. Universidade Federal do Rio de

Janeiro, Brasil, 2002.