Basic HTML Version

758

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 6

Pull Off test to evaluate the compressive strength of concrete: an alternative to Brazilian standard techniques

1. Introduction

In reinforced concrete structures, the strength of concrete is one

of the most important properties, being the main parameter used

for design. Ways to evaluate this property in finished structures or

structures in use, without damage to its functionality or appearance,

have been the concern of engineering professionals over the years.

In civil engineering there are many test methods to evaluate the

strength of concrete. The most frequently used test is to measure

the compressive strength of concrete at age of 28 days using

simple compression in cylindrical and prismatic specimens. The

simple compression test on cylindrical specimens is standard both

in Brazil and the USA [1, 2], and in Europe, both shapes are stan-

dardized [3, 4].

Despite the ease of implementing this kind of test, both in terms

of specimen preparation as well as in getting results, the test re-

quires planning before the execution of structures, through the

creation of test specimens. This fact does not favor the inspections

in finished structures or control the development of the material

resistance over time.

In recent decades, other tests were developed, like non-destruc-

tive tests which, through faster, simplest and more economical

processes allow obtaining information on the concrete properties.

These tests also provide an estimate for the compression strength

of the measured concrete in situ, eliminating the need of extraction

of many specimens for determination of the compressive strength

of the inspected structures. The most popular tests are the re-

bound hammer and the ultrasound test, which are standard in Bra-

zil. There are also others tests such as penetration resistance of

hardened concrete, Pull Off, Pull Out and Break Off, presenting

themselves as viable alternatives [5, 6, 7, 8, 9, 10].

The non-destructive techniques produce little or no damage to the

inspected part, can be implemented in concrete structures in use

and allow the detection of problems still in early stages. This can

be an advantage, especially from a financial perspective, because

when a problem is detected at an early stage the necessary inter-

ventions can be done before the complete damage of the structure.

The choice of the test method depends on several factors such as

structure access, cost of intervention, damage caused during the

execution of the test, speed of execution, characteristics and type

of assessment to be achieved [9]. This paper discusses the re-

bound hammer test [11] and the ultrasound test [12], standardized

in Brazil, in addition to the Pull Off test, as standardized in Europe

by BS 1881 part. 207 [13].

2. Non-destructive test

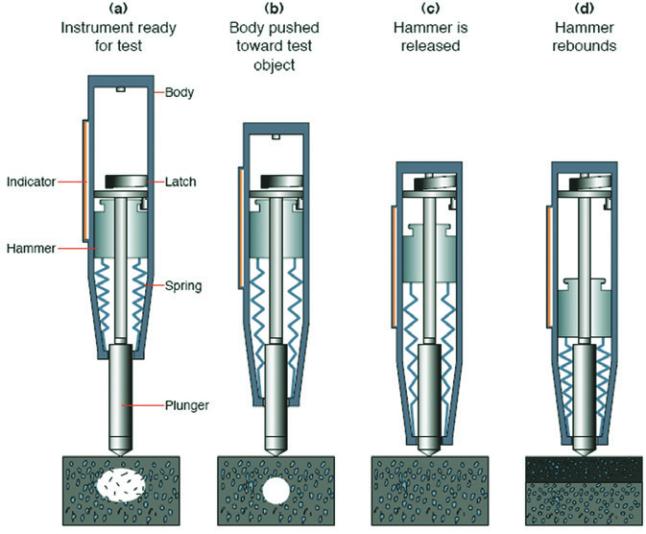

2.1 Rebound hammer test

Currently, the non-destructive and most commonly used test is

the rebound hammer test. This method is based on measuring the

surface hardness of the concrete and, as the response variable,

has an index that can be used to estimate the resistance from cor-

relation curves. The rebound hammer is portable, simple and in-

expensive. This equipment enables the fast acquisition of a large

amount of data.

The equipment consists of a cylindrical tube in whose interior there

Figure 1 – Rebound Hammer test [14]