Basic HTML Version

164

IBRACON Structures and Materials Journal • 2013 • vol. 6 • nº 1

Concrete compressive characteristic strength analysis of pile caps with three piles

The increase in the concrete compressive strength (f

ck

) caused a

reduction in the cracking intensity, as shown in Table 7, due to the

increase in the concrete tensile strength. It is worth noting that the

cracking process begins in the region where the structure reaches

the ultimate tensile strength, thus beginning a microcracking process,

which leads to stress reduction until the material reaches the critical

opening crack (w

c

) – Figure 4a –, when a complete separation of the

crack sides takes place. Therefore, the higher the concrete’s ultimate

tensile strength, the higher the pile cap’s cracking resistance.

Having mentioned that, in Table 8 a correlation between the pile

cap’s crack intensity reduction according to the concrete tensile

strength increase is presented. From model 1 to model 3 there

was an increase of 21,32% (from 2,58 MPa to 3,12 MPa) in the

concrete tensile stress and a reduction around 30% in the crack

opening intensity.

3.3 Compressive struts stresses

In all three pile caps analyzed compressive struts were developed

with equal divisions of the stress flow at the bottom of the column’s

cross-section in direction to the piles, as shown in Figure 8.

In addition, in all models struts compressive stresses were con-

centrated in the piles superior cross-section region closer to the

column, corroborating Delalibera’s [6] statement that in the inferior

nodal zones the struts stresses are not uniformly distributed.

The concrete compressive strength led to a proportional in-

crease in the struts compressive stresses, as demonstrated in

Table 9. The concrete’s compressive strength increase from 30

MPa to 40 MPa (+33,33) generated an increase of 38,09% in

the struts stresses.

Notwithstanding, as shown in Figure 8, pile caps stress flow did not

have a perceptible modification.

In all models, the inferior nodal zones stresses were higher than

the concrete compressive strength (f

ck

), indicating concrete col-

lapse, as shown in Table 10.

There was also the development of tensile stresses in the nodal

zones and along the struts which reached values higher than the

concrete tensile strength, as can be seen in Table 11, demonstrat-

ing the concrete splitting.

3.4 Ties tension stresses

Tie bars yielded in the ultimate load in all three models. Moreover,

in the inferior nodal zones an abrupt reduction in the ties tensile

stresses occurred due to the positive action of the compressive

struts in the steel bars.

From figures 9 to 11, it is possible to observe that, in the pile cap’s

span, reinforcement tensile stresses were practically constant with

values around 590 MPa. Nonetheless, at the beginning of the nod-

al zones, tensile stresses were greatly reduced, reaching very low

values, around 5 MPa in the borders of the bars and in the hooks.

These results prove that tie hooks are not necessary, since tie bars

anchorage is made almost totally in the inferior nodal zones which

receive the positive influence of the compressive struts.

Ties tensile stresses in the inferior nodal zones and at the bars bor-

ders were not altered by the increase in the concrete compressive

strength, as shown in the Figures 9, 10 and 11.

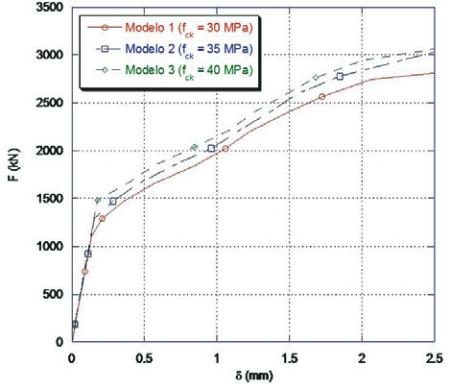

Figure 7 – Pile caps load

versus

displacement graphic

Table 7 – Opening cracks values

Load values

(kN)

F=920

F=1.840 F=2.750

Maximum

opening

crack on

the pile

cap’s

surface (mm)

Model 1

0,022

1,52

3,88

Model 2

0,019

1,27

3,33

Model 3

0,015

0,97

3,20

Table 8 – Opening cracks variation (

) in relation to the concrete tensile strength

f

tk

f

tk

F=920

F=1.840

F=2.750

Opening cracks

variation (%)

Model 1

2,58 MPa

-

-

-

-

Model 2

2,83 MPa

+9,69%

-13,63%

-16,45%

-14,17%

Model 3

3,13 MPa

+10,60%

-21,05%

-23,62%

-4,00%