Basic HTML Version

24

IBRACON Structures and Materials Journal • 2013 • vol. 6 • nº 1

Automation of the evaluation of bonded and unbonded prestressed concrete beams, according to brazilian

and french code specifications

area required for w

k

calculation. The maximal crack width value

found in the analysis (w

k

= 0.000125 mm) was lower than that es-

tablished by the Brazilian norm (w

k,lim

= 0.2 mm), thereby ensuring

the member safety regarding SLS-W.

In the French norm, SLS-W is evaluated only by comparison of

reinforcement stresses, and therefore, the discretization of each

stressed reinforcement module in an extremely refined grid is not

required. Analyzing the strain graphs of each passive reinforcement

layer, it is observed that layers 7, 8, 9, 10, and 11 present tensile

stresses in the sections located at the beam’s ends. In these sec-

tions, reinforcement layer tensile stress was compared with limit

stress. As the corresponding limit strain is equal to 1.143‰, that

is, much higher than the obtained maximal strain (0.538‰), beam

safety is ensured relative to SLS-W.

Figures 23 and 24 show the cracking tables calculated according

to the Brazilian and French norms, respectively. It is observed that

the central sections are not cracked. Crack width was determined

for the upper edge of the regions close to the foundations.

Based on the cracking tables of this example, it was found that

most sections were still completely compressed at the end of SLS

evaluation. In addition, according to both Brazilian and French

norms, most lower and central fibers were still compressed (-1),

differently from the upper fibers, close to the foundations, which

already presented some cracking (2).

Figure 25 shows a photograph of the assembly of the cover beams

in the structure of Feevale theater in Novo Hamburgo, RS, Brazil.

The beams arrived at the site with an initial hogging of approximately

4cm, and sagging was virtually null after total load was applied.

After ULS verification was analyzed according to the Brazilian and

French norms, ultimate moment values were compared with resis-

tant moment values. According to the criteria of the Brazilian norm,

the resistant moment (9,460 kN.m) was compared with ultimate

moment (8,015 kN.m) and an additional safety factor equal to 1.18

was obtained for breaking. When using the French norm, the re-

sistant moment value (9,896 kN.m) was 1.26 times higher than the

ultimate moment (7,860 kN.m), which is lower than that obtained

with the Brazilian norm due to different load increment coefficients.

As in both cases ultimate moment was lower than the resistant mo-

ment, element safety regarding rupture is ensured.

4.2 Unbonded partially prestressed beam

In order to illustrate the use of unbonded reinforcement in evalu-

Figure 18 – Cross-sections forces (kN, cm) - Brazilian code specification (frequent load combination)

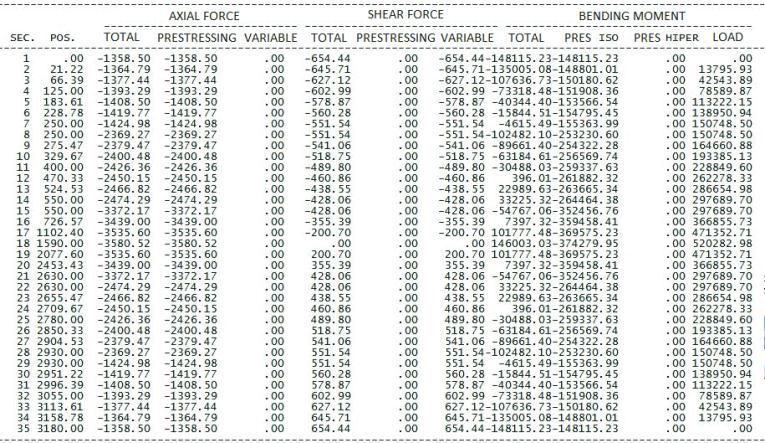

Figure 19 – Axial and Shear forces - Brazilian code

specification (frequent load combination)