Basic HTML Version

533

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 4

A. E. P. G. A. JACINTHO | V. P. SILVA | J. A. V. REQUENA | R. C. C. LINTZ

| L. A. G. BARBOSA | L. L. PIMENTEL

The oven temperature was monitored using internal rod thermo-

couples coupled to a data acquisition system.

After the tests in the oven, the models were cooled and tested with

a monotonic load on the 5000-kN press.

4.1 Experimental results and data analysis

Table 2 presents the stress values that caused the initiation of

plastic deformation at room temperature, as obtained by SIMÕES

[3], and at high temperatures, as obtained by ARAÚJO [5]. Figure

5 was prepared to better visualize the data. The stress values

for plastic deformation were obtained according to the procedure

presented by HAN et al. [6].

For the columns tested at 30 and 60 minutes, which were then

cooled and tested under a static load, it can be observed that the

yield strength was less than that obtained for the same columns

left at room temperature. This reduction in strength occurred main-

ly for the columns that were loaded during heating. The columns

with a 30-minute exposure time that were not loaded during the

test were not different in terms of yield strength from those that

were not heated.

Table 3 presents the maximum axial yield strength values for the

columns at room temperature and the columns that were heated

and cooled. Figure 5 was prepared to better visualize the data.

Figure 6 shows the Specific Linear Stress-Strain Diagram of col-

ture elevation curves for different cases, as well as the standard fire

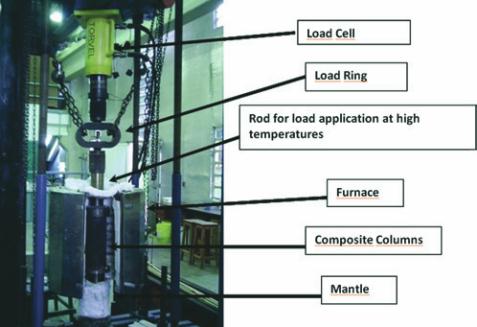

curve ISO 834 [1]. A test system was prepared that coupled the

oven with the 600-kN press to allow static loads to be applied and

maintained while the temperature was varied, as shown in Figure 4.

Figure 4 – High-temperature load

application system

Table 2 – Maximum temperatures and yield strengths

F – Yield strength for the columns at room temperature

esc

q

F – Yield strength for the columns after cooling

esc,

Group

Composite TRRF

Oven

Temp.

Steel

Temp.

Concrete

Temp.

F

esc

q

F

esc,

F

esc

q

F

esc,

Column (min)

(°C)

(°C)

(°C)

(kN)

(kN)

C 6-30

1

30

890

800

290

780

640

0.821

2

30

890

500

150

780

750

0.962

S 6-30

1

30

880

570

150

780

780

1

C 6-60

1

60

1,200

1,140

690

780

500

0.641

2

60

940

630

370

780

680

0.872

S 6-60

1

60

940

670

440

780

700

0.897

C 8-30

1

30

750

700

170

1,150

950

0.826

2

30

880

500

150

1,150

S 8-30

1

30

880

450

170

1,150

1,150

1

C 8-60

1

60

860

810

660

1,150

1,000

0.870

2

60

940

630

380

1,150

1,150

–

–

–

–

–

–

1

S 8-60

1

60

900

640

470

1,150

C 63-30

1

30

750

550

125

1,200

2

30

890

450

100

1,200

1,000

0.833

S 63-30

1

30

890

450

100

1,200

1,190

0.992

C 63-60

1

60

945

650

250

1,200

1,050

0.875

2

60

940

590

230

1,200

880

0.733

S 63-60

1

60

950

700

330

1,200

910

0.758