Basic HTML Version

535

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 4

A. E. P. G. A. JACINTHO | V. P. SILVA | J. A. V. REQUENA | R. C. C. LINTZ

| L. A. G. BARBOSA | L. L. PIMENTEL

tube, at the steel-concrete interface and in the concrete core.

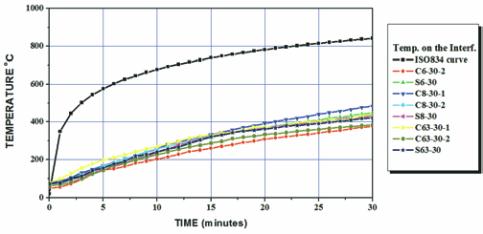

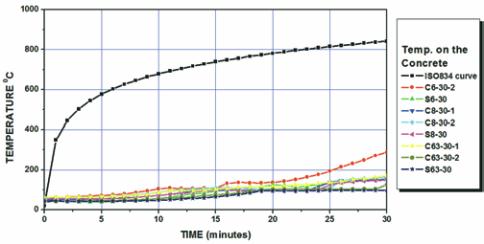

Figures 9 and 12 show the behavior of the temperature in the con-

crete core where it is evident that, as expected, the temperature

was lower in the tubes with larger diameters and thicknesses.

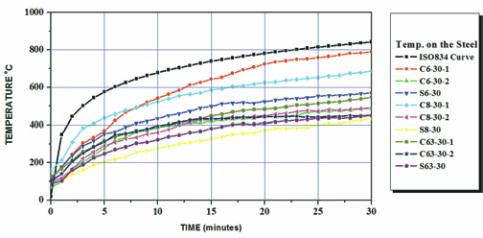

The graph in Figure 13 shows the temperatures of the columns

tested in the oven with and without loads at 30 min. and 60 min.

The results indicate that at 30 min. the steel tube surface was ap-

proximately 400 to 500ºC, with practically no loss of load bearing

capacity for this temperature range. In the case of a 60-minute ex-

posure time, however, the columns showed temperatures ranging

from 600 to 700ºC. An indication of the influence of the thickness

of the tube wall and the diameter of the tube on the temperature of

the concrete core can also be observed.

Figure 6 – Maximum axial stress: columns at room temperatures X columns after exposure

to high temperatures

FORCE kN

TESTS

Figure 7 – Stress-strain diagram for the columns

at room temperature and the columns

after exposure to high temperatures

Figure 8 – Temperature vs. time curves in

the steel with a 30-minute exposure time

Figure 9 – Temperature vs. time curves at the

steel-concrete interface with a 30-minute

exposure time

Figure 10 – Temperature vs. time curves

in the concrete core with a 30-minute

exposure time