Basic HTML Version

452

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 4

Effect of red mud addition on the corrosion parameters of reinforced concrete evaluated by

electrochemical methods

1. Introduction

The world’s production of bauxite in 2009 was 205 million tons,

and the main producing countries were Australia, China, Brazil,

Guinea, India and Jamaica. Ranking third in worldwide production

in 2009, Brazil produced 26.6 million tons of bauxite. It also has

the world’s third largest bauxite ore reserves (around 3.5 billion

tons), concentrated mainly in the northern part of the country (state

of Pará) [1]. Roughly 0.3 – 1.0 tons of red mud waste are gener-

ated per ton of aluminum produced. Brazil has discarded about

10.6 million tons/year of caustic red mud in recent years and the

worldwide generation of red mud exceeds 117 million tons/year [2].

The storage of large quantities of alkaline residue (red mud) is expen-

sive (between 1 and 2% of the price of alumina), requiring large dispos-

al areas (about 1 square kilometer for five years of production for a fac-

tory producing 1 million tons of alumina per year) and causing serious

environmental problems [3]. Therefore, the use of this waste in cement

matrices is very attractive since the high amount of cement consumed

worldwide is compatible with the high generation of this waste.

Alkaline matrices such as those provided by Portland cement in

mortars and concrete are commonly used in waste conditioning.

They are inexpensive, have an extensively documented history of

safe use, and are a draw-upon readily-accessible technology. Al-

kalinity greatly reduces the solubility of many hazardous inorganic

species and inhibits microbiological processes. Moreover, since

these matrices require water for hydration, they may readily incor-

porate wet wastes

[1] such as red mud. Red mud was chosen for

this study due to its high alumina and iron oxides contents.

The search for an economically and environmentally viable alterna-

tive has led to the study of red mud for various applications, such

as adsorbent for the removal of heavy metals from aqueous solu-

tions [4], building materials such as bricks [5], ceramics and tiles [6],

ceramic glazes [7], as polymer-based composites to replace wood

[8], iron-rich cement [9, 10], component of clinker [3, 9, 10], and the

addition to mortar and concrete formulations was also reported [11].

The use as common building material has been suggested as an

alternative that ensures high rates of consumption [12].

The high alkalinity of red mud, which was initially a factor of envi-

ronmental concern, now emerges as a major asset in the attempt

to use red mud as an inhibitor of reinforced concrete rebar corro-

sion by retaining its passivity. To evaluate this possibility, rebar

corrodibility was examined by corrosion potential and electrical

resistivity measurements.

By analyzing the results compared with reference samples (with-

out waste addition), intended to determine the viability of the red

mud as an addition to Portland cement matrices providing an ap-

propriate and less costly destination.

Thus, we sought an alternative for two actually problems: corrosion

in reinforced concrete, which consumes millions of dollars with the

maintenance and revitalization of infrastructure, and the environ-

mental damage caused by industrial solid waste disposal, one of

the biggest questions to be solved in this century.

2. Materials and Methods

2.1 Materials

Ordinary CP-II 32 Z Portland cement (OPC), according to the Brazil-

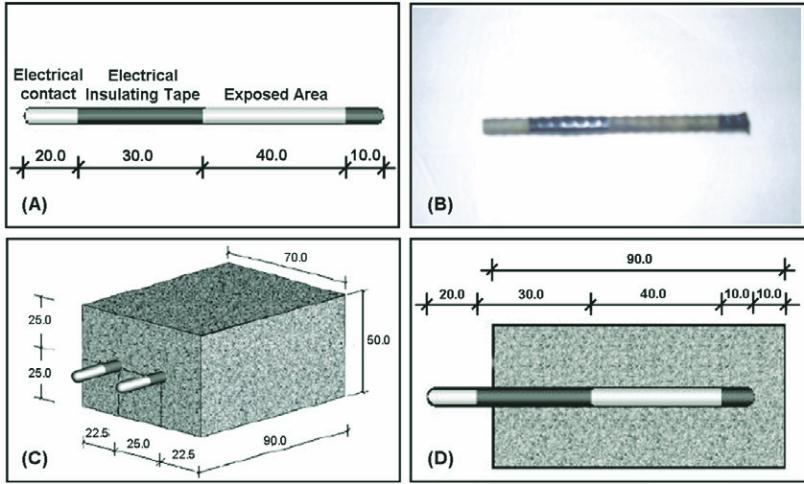

Figure 1 – (A) and (B) Scheme of the exposed rebar area (in mm); (C) sample

dimensions (in mm); and (D) steel rebar positions in concrete samples