Basic HTML Version

456

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 4

Effect of red mud addition on the corrosion parameters of reinforced concrete evaluated by

electrochemical methods

surements in the wet and dry states (0%). Due a larger network of

capillary pores, the reference samples presented a higher absorp-

tion capacity (capillary suction) and greater difficulty in losing this

moisture (lower porosity) than the other samples.

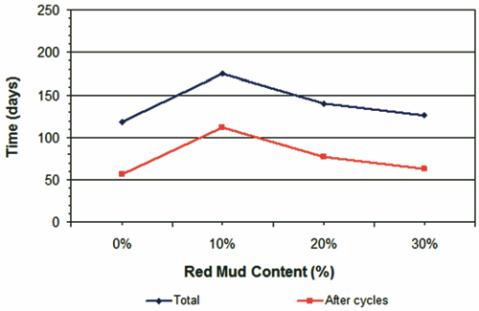

The tests were interrupted when the “unsafe potential” was

reached in samples in the dry state. For a better view, these results

are presented in Figure 5. As can be seen, the reinforcing bars in

specimens containing red mud took longer to depassivate than the

reference samples, regardless of the amount of red mud added.

These results indicate only the onset of the corrosion process,

without, however, presenting quantitative information about the

phenomenon. Although they reached the end of test more quickly,

the specimens that reached the unsafe potential continued to be

subjected to wetting and drying cycles for up to 180 days, when the

last samples (10%) reached this potential. Thus, it was possible to

calculate the corrosion rate of all the samples according to equa-

tion (A). The results are shown in Figure 6.

According to these results, the higher the content of red mud the

lower the corrosion rate, which reached stability between 20 wt%

and 30 wt% of red mud content. This behavior may be due to three

isolated factors or to their combination: i) increasing alkalinity in the

region near the steel-concrete interface; and/or ii) greater anchor-

ing of chloride ions due to the presence of sodium aluminosilicates,

which prevent the free movement of these ions and make them un-

available to start the corrosion process, as discussed with respect

to the results of the chloride migration test; and/or iii) according

to MCCARTER apud SANTOS [13], larger pores (existing in the

specimens containing red mud) lose water more easily than the

small and tortuous pores that are present in the reference sample.

Figure 5 – Rebar corrosion onset period

as a function of red mud content

Figure 6 – Corrosion rate of steel bars

embedded in reinforced concrete specimens,

calculated after the corrosion potential

test, as a function of red mud content

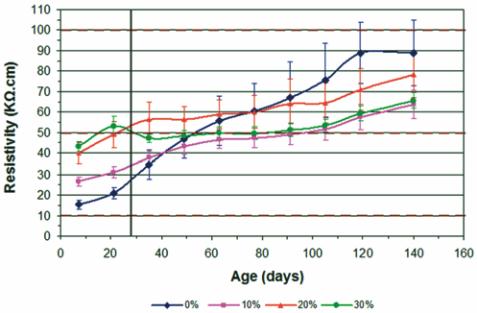

Figure 7 – Electrical resistivity of concrete

specimens containing red mud,

as a function of age

Figure 4 – Evolution of the corrosion potential

of rebars embedded in reinforced concrete

specimens containing red mud, as a function

of age