Basic HTML Version

476

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 4

Parametric study on the behaviour of bolted composite connections

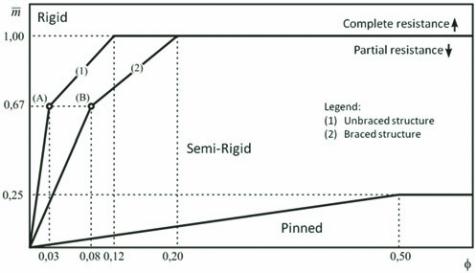

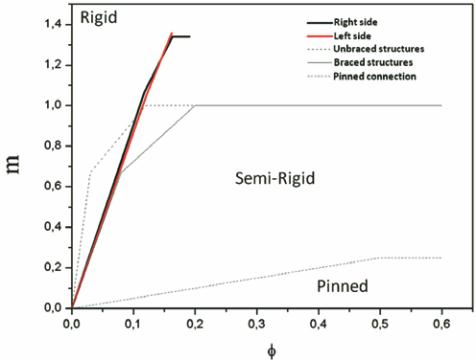

code 3 [9] for unbraced and braced structures.

The classification was done for the situation that the connection

was subject to negative bending moment, because it is the effort

imposed to the structure for the most time of its life. The results

obtained for both sides was that the slab contributed to resist the

efforts, therefore the connection had the resistance enhanced and

reached the classification of rigid with full resistance to braced

structures, as can be seen in Figure 14.

Table 1 – Experimental stiffness of reference model

Left Side

Right Side

Inicial

Final

Inicial

Final

Positive

Moment

Negative

Moment

Positive

Moment

Negative

Moment

Stiffness (k)

kNm/rad

34324,29 26398,87 33656,42

36360,76 28311,42 23178,00

k /k

final

inicial

-

0,77

0,98

-

0,77

0,64

Table 2 – Beam properties used

in the classification of the stiffness

Beam Properties

4

Moment of inertia (Iz) cm

2887,30

3

Modulus of plastic resistance (Zx) cm

253,60

Plasticization Moment (Mp) kNm

88,76

Length (Lb) mm

1650,00

Yielding Stress (fy) MPa

350,00

Elastic Modulus (E) MPa

230000,00

Figure 13 – Connections classification specified

by Eurocode 3

5. Numerical modeling

5.1 Materials

5.1.1 Properties

The material properties used in the numerical model were deter-

mined in the characterization tests, and others, such as fracture

energy of concrete, which could not be determined experimentally,

was determined based on requirements of the CEB MC 90 [10],

assuming that in the production of concrete was used aggregates

with maximum dimension of 19 mm. For the steel profiles the elas-

tic modulus and yielding stress were determined by tensile tests

according to ABNT NBR 6892:2002 [11] code.

The shear connectors used in the model were the same used in

research [7], and the properties adopted for them were taken from

there. For elastic modulus of the bolts and shear connectors were

adopted nominal values characteristic of each material.

Related to the reinforcement bars of the slab, the properties adopt-

Figure 14 – Classification of model 1

by Eurocode 3