Basic HTML Version

856

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 6

A study on the behavior of beam-column connections in precast concrete structures:

experimental analysis

3.5. Mechanical properties of materials

3.5.1 Concrete

The compressive strength of cast on site concrete was obtained

by testing three cylindrical specimens with dimensions of 200

mm x 100 mm. The characterizations tests were conducted one

day after the test of the connections, when the specimens were

eight days old. The average of the compressive strength was

25, 7 MPa.

The values of the compressive strength of the precast concrete el-

ements were reported by manufacturer. The compressive strength

was about 40 MPa and the elastic modulus was 30270 MPa.

3.5.2 Grout

The grout was used to fill the interface between the beam and the

column, the hole of the dowels and hole in the column where the con-

tinuity reinforcement was located. The type of grout used in the pro-

totypes was a mixture based on cement Portland, natural aggregates

and additives which allow the utilization in operations of anchorage.

This product develops high mechanical strength without shrink-

age and it is indicated to grout services or to be used as mortar

repairs. This grout was chosen due to its fluidity maintained for

a long time, which allows working in hard to reach areas like

the case of the fulfillment of the holes and the interfaces. Ac-

cording to manufacturer’s data, this grout can achieve a com-

pressive strength of 20 MPa in twenty-four hours and 52 MPa

at twenty-eight days.

The characterizations tests of the cylindrical specimens of grout

were performed with 26 days and the results confirmed the data

provided by the manufacturer. Thus, it can be considered that in

the date of the connections test, when the grout was 15 days old,

it had reached 40 MPa of compressive strength.

4. Experimental results

The tests of the connections models tested presented satisfac-

tory behavior because they reached a load which exceed the

Figure 11 – Test set up

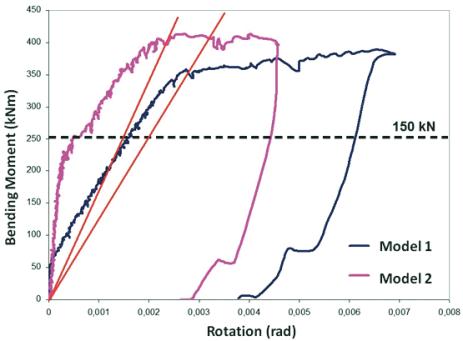

Figure 12 – Bending moment

versus

rotation curves

with the indication of secant stiffnesses (red lines)

Table 2 – Stiffnesses of Model 1 and 2

Model

Secant stiffness

kNm/rad

Project stiffness

kNm/rad

1

120 689

155 772

2

181 818

511 993