Basic HTML Version

760

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 6

Pull Off test to evaluate the compressive strength of concrete: an alternative to Brazilian standard techniques

application in structural elements of short section. One exposure

face of the element is enough to testing. Another important point is

the fact that the equipment used in the implementation of Pull Off is

the same used in adhesion assays in mortar, standardized in Brazil

for some years, which may facilitate its use.

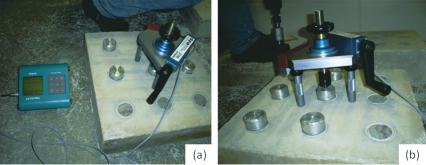

The Pull Off test is based on the concept that the traction force

required to pull a metallic disc bonded to a surface layer of con-

crete is associated with the compressive strength of the material

[19]. In the test, the traction is axially transmitted to the disc previ-

ously bonded to the concrete. After a period of time enough to

cure the resin (adhesive), a traction force is applied to the disc

using a mechanical portable system [Figure 3 (a) and 3 (b)]. The

gradual increase of force (Megapascal (MPa)) can be observed in

equipments that have an integrated digital manometer. The tensile

force that causes breakage associated with the calibration curves

makes possible to estimate the compressive strength [5].

There are many factors that may influence the results obtained and

are responsible for variability in this test. In addition to the compo-

sition and concrete properties, also have influence the variation on

the rupture surface, the orientation and position of the aggregate

onto the disc, the disc material (steel or aluminum), the disc diam-

eter and thickness (ratio e/d), the backpressure system (ring or

tripod) and the speed of load application [7].

In Brazil, the Pull Off test is traditionally used to evaluate the adhe-

sion strength of mortar. A difference of this test applied to concrete

and mortar is the presence of coarse aggregate which becomes

an influencing factor. It is thought that the shape and position of

the aggregate over the disc surface influence the results, but this

is an issue that requires further studies to determine the conditions

of this variable.

Another factor of interference in the results is the presence of re-

inforcement in the area where the metallic disc is bonded to the

test performance. The lack of control of this variable could cause

distortions in the results damaging the efficiency of the inspection.

Therefore, it is recommended that before bonding the discs, a lo-

cator is used to ensure that the disc is not bonded in areas where

the presence of reinforcement occurs.

Grullón et al. [21] in their paper for evaluating the strength of con-

crete using ultrasound for different mix proportion of concrete and

humidity condition got a low sensitivity for this evaluation. For

strength of specimens ranging between 41 and 64 MPa, the speed

of ultrasound propagation ranged from 4425 - 4721 m/s, with

very

close values, susceptible to experimental errors.

Machado et al. [22], using rebound hammer tests, penetration

resistance and ultrasound to determine concrete strength, con-

cluded that ultrasound showed the lowest correlation for obtaining

the resistance. Popovics et al. [23] mentions that the estimate of

resistance cannot be obtained with high accuracy using just the

value of the ultrasound test. The author reports a lack of theoretical

relationship between the magnitudes listed, although in other tests

that also happens.

The propagation speed can be influenced by several factors being

the most important: the run length, size of the structure to be tested,

the presence of reinforcement, as well as temperature and humidity

condition of the concrete. Results with high accuracy are influenced

by preparation of surface to be tested, binding of the transducers

and the method of selection and placement of transducers.

2.3 Pull Off

The Pull Off test was developed in England in the 70s, with the

aim of determining the strength of concrete in situ, due to problems

with concrete produced with high-alumina cement [5]. The test has

been used successfully since then to evaluate the resistance of

concrete. This test can also be used to verify the adhesion strength

of the concrete repairing material [24].

The Pull Off test is not standardized in Brazil, but countries like Eng-

land and USA recognize this method as a possibility in studies to es-

timate the compressive strength in the field [13]. This approach has

revealed consistent results; in addition, the unsatisfactory results are

visible after the test by observing the rupture surface.

Due to its simplicity, the test may be performed in the structure,

including without planning prior to concreting. The technique is ef-

fective for use in beams and slabs and also shows appropriate

Figure 3 – Pull Off test: (a) Test in progress and (b) equipment