Basic HTML Version

1. Introduction

The transportation time of concrete from the first addition of water

until the beginning of its discharge at the construction site must be,

according to NBR 7212:

a) fixed, so that the end of compacting does not occur after the ini-

tial setting of the cast concrete and the layers or parts adjacent

to this batch;

b) under 90 min and fixed, so that by the end of the discharge no

more than 150 minutes have elapsed, in case of using a vehicle

equipped with an agitator;

c) under 40 min and fixed, so that by the end of the discharge no

more than 60 minutes have elapsed, in case of using a vehicle

without an agitator.

The transportation of pre-mixed concrete to the construction site

must be undertaken as fast as possible in order to minimize the

effects of stiffening and loss of workability, and to allow appropri-

ate setting and finishing after casting. Under normal conditions,

there is generally negligible slump loss during the first 30 minutes

after the initial hydration of Portland cement. When the concrete

is agitated at low speed or when it is periodically remixed, there

may occur some slump loss with time, which does not generally

cause any serious problems for the casting and setting of fresh

concrete in the first 90 minutes (Mehta and Monteiro, 2008).If that

time interval is exceeded, it is still possible to add plasticizers and/

or superplasticizer to recover the concrete’s slump for subsequent

casting and setting, as slump correction with water causes signifi-

cant damage to the mechanical properties.

The workability of concrete is the property that determines the ef-

fort required to manipulate a specific amount of fresh concrete, with

minimal loss of homogeneity. The term manipulate includeeesarly

stage operations, such as casting, setting and finishing (Mehta and

Monteiro, 2008).

The change from the fluid to the rigid state is, in general terms,

defined as setting (NEVILLE, 1995). Setting is the term used to

designate the stiffening of the cement paste, even though the defi-

nition of

stiffening

of the paste is arbitrary. According to MEHTA

and MONTEIRO (1994), what causes the stiffening of the paste

and, finally, its setting and hardening is the gradual loss of free wa-

ter due to hydration reactions, physical adsorption on the surface

of the hydration products with poor crystallinety (such as C-S-H

and ettringite) and evaporation. The beginning of the setting marks

the moment when the paste becomes unworkable. Consequently,

the casting, compacting and finishing of the concrete become dif-

ficult after this stage.

The paste does not solidify suddenly, it needs considerable time

to become totally rigid. The time necessary for the paste to totally

solidify marks the end of the setting, which should not be long, so

that other constructive activities can be resumed as soon as pos-

sible after the concrete casting (MEHTA and MONTEIRO, 2008).

The terms initial set and final set are used to arbitrarily describe

specific states of the setting. Although in the interval between the

initial and the final set, the paste acquires a certain resistance,

from a practical point of view, the development of the paste’s resis-

tance is considered after the end of the setting, when the harden-

ing starts (NEVILLE, 1995).

The standard test to determine setting times is the needle pen-

etration test. It is done almost universally by using the Vicat ap-

paratus. In Brazil, the testing method is prescribed by the NBR NM

65 (2002). The initial set time is designated as the time elapsed

between the moment water is added to the cement and the mo-

ment when the Vicat needle, with standard diameter and mass,

penetrates the standard consistency paste and stops 1 mm from

the bottom of a particular mold. Therefore, for each cement, it is

necessary to determine the water content of the paste that pro-

duces the standard slump (NBR NM 67, 1998). The final set time is

defined as the time interval between the pouring of water into the

cement and the first of three successive readings equal or higher

than 38 mm, done in the normal consistency paste, using a Vicat

needle (SILVA, 2007).

Specification norms establish the acceptable limits for each Port-

land cement designation. NBR 5733 – CPV, NBR 5735 – CPIII,

NBR 5736 – CPIV and NBR 11578 – CPII establish that the initial

set time should be equal to or over1 hour.

The reactions between cement and water are the basic

799

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 6

A. B. ROHDEN | D. C. C. DAL MOLIN | G. L. VIEIRA

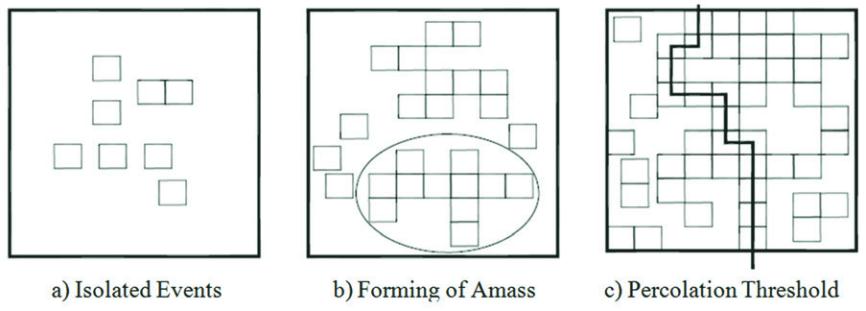

Figure 1 – Schematic representation of the notions of the percolation theory

according to ACKER (1988) apud SILVA (2007)