Basic HTML Version

803

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 6

A. B. ROHDEN | D. C. C. DAL MOLIN | G. L. VIEIRA

with other equipment and, especially, with a greater volume of

concrete mixes.

However, it is important to emphasize that the employment of su-

perplasticizers, along with regular agitation, allowed the casting

of the concrete to be done over a time interval 2.5 times longer

than what is prescribed by NBR 7212, while maintaining its me-

chanic performance.

4. Conclusions

This study shows that differently from the standards set by

NBR 7212 and from what is widely indicated in the literature,

the concrete casting and finishing time can be extended be-

yond150 min, to up to 360 min, as long as slump is maintained

through the use of superplasticizers (maintaining the water/

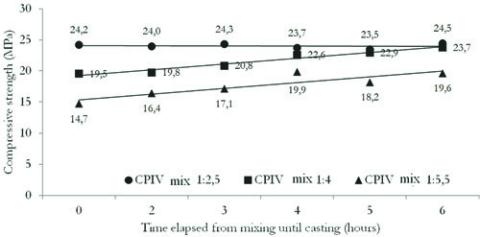

Figure 4 – Compressive strength of the concrete

made with CPIV, at seven days

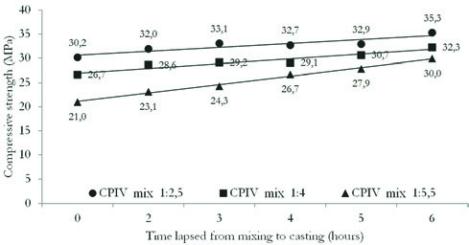

Figure 5 – Compressive strength of concrete

at twenty eight days, made with CP IV

Table 4 – Variance analysis

Source

Test

SQ

GDL

MQ

F

Probab

Comment

A: Type of cement

8780.53

1

8780.53

519,32

0.00%

S

B: Breaking age

2787.30

1

2787.30

164,85

0.00%

S

C: Compacting time

1056.91

5

211.38

12.50

0.00%

S

D: Mix proportion

1792.62

2

896.31

53.01

0.00%

S

AB

24.48

1

24.48

1.45

23.09

NS

AC

258.96

5

51.79

3.06

1.18%

S

AD

262.74

2

131.37

7.77

0.06%

S

BC

146.57

5

29.31

1.73

13.09%

NS

BD

77.52

2

38.76

2.29

10.49%

NS

CD

241.03

10

24.10

1.43

17.52%

NS

ABC

65.99

5

13.20

0.78

56.54%

NS

ABD

108.75

2

54.37

3.22

4.32%

S

ACD

406.53

10

40.65

2.40

1.16%

S

BCD

414.57

10

41.46

2.45

1.00%

S

ABCD

284.74

10

28.47

1.68

9.03%

NS

Error

2316.35

137

16.91

–

–

–

–

–

–

–

Total

19025.58

208