Basic HTML Version

288

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

Nanotechnology and Construction: use of nanoindentation measurements to predict macroscale elastic

properties of high strength cementitious composites

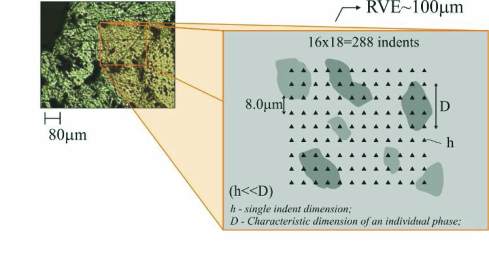

a sufficient content. Thus, it could be considered as a representa-

tive volume element (RVE) on the matrix level (level I) having the

dimension ~100 mm. Individual indent size (depth of penetration

h) was chosen to be h ≈ 200 nm, [19], so that the affected volume

under the indenter, which can be estimated as 3×h (i.e. ~600 nm),

was smaller than the characteristic sizes of inclusions to avoid

significant phase interactions. However, in the dense matrix of a

HPCC full exclusion of interactions can hardly be achieved since

it presents several phases of different stiffness. Due to surface

roughness, which cannot be further decreased by mechanical way,

[23], the indent size must be kept in hundreds of nm. The indent

size 100~300 nm also suits well the concept of grid indentation on

cement pastes, [19]. It can be assumed that hard quartz filler, with

maximum ~60 mm size, in larger volumes can also cause stiffening

of less stiff phases like C-S-H gels during indentation. The error

incorporated into the measurements can be roughly quantified by

FEM computation as 13~25%, [24]. Similar errors are incorporated

into measurement of stiff inclusions surrounded by a compliant

matrix, however their content is smaller and thus their influence

also decreases. It can be assumed that such errors are naturally

included in nanoindentation measurements and should be consid-

ered in the final comparisons.

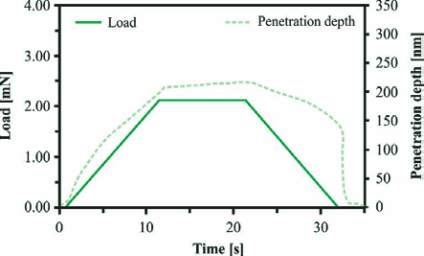

The nanoindentation loading regime contained loading at 12 mN/

min, holding for 10 seconds and unloading at 12 mN/min as shown

in Figure 4b. The holding period of 10 seconds with constant force

was added mainly to minimize creep effects on the elastic unload-

ing, [25].

The elastic modulus of the analyzed phase was determined ac-

cording to the Oliver-Pharr methodology, [10]. The analysis is

based on Eq.(1) to define the indentation (reduced) modulus:

(1)

S

A

E

r

p

b

2

1

=

(2)

max

hhh

P

d

d S

=

=

where S, which is defined by Eq.2, is the contact stiffness assessed

as a slope of the unloading branch at the maximum depth h

max

and

the peak load, A

c

is the projected contact area at the peak load, and

β is the geometrical correction factor introduced to correct the non-

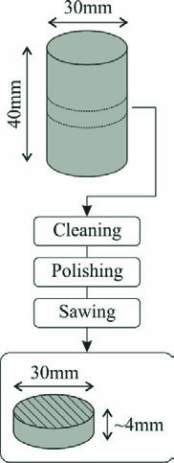

Figure 3 – Specimens for nanoindentation

test: initial and final configuration

Figure 4 – Nanoindentation tests: (a) Indentation grid, and (b) loading and penetration depth diagram

A

B