Basic HTML Version

290

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

Nanotechnology and Construction: use of nanoindentation measurements to predict macroscale elastic

properties of high strength cementitious composites

3.2 Experimental results in hardened state -

Microscale analysis

3.2.1 Nanoindentation

A total of 288 indents to the cementitious matrix were performed.

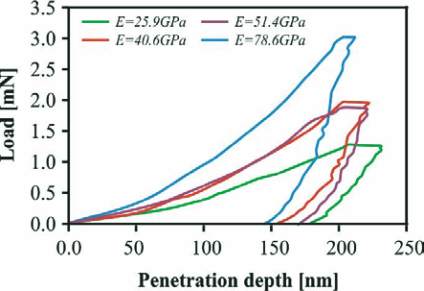

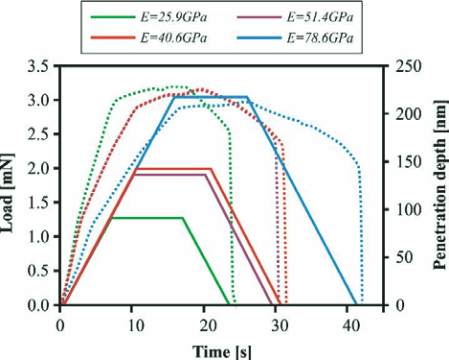

Examples of the load-penetration curves and related load/penetra-

tion-time diagrams showing indents to differently stiff phases are

presented in Figure 5 and 6, respectively.

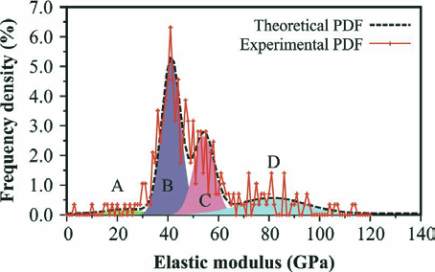

All relevant indents were analyzed by the Oliver-Pharr method,

[10], for an elastic modulus with the assumption of constant Pois-

son’s ratio 0.2 for all indents, since the influence of the selected

Poisson’s ratio in the relevant range 0.18−0.22 on the evaluation

is very small, [17]. Subsequently, the frequency plots, with bin

size set to 1.0 GPa, and related experimental probability density

functions (PDFs) were computed. The deconvolution method was

applied to PDFs as illustrated in Figure 7. The obtained results

are listed in Table 6.

As mentioned above, the results are considered as results re-

ceived on mechanically distinct phases and there is no intention

to link them with pure chemical phases, such as C-S-H gels with

different densities, Portlandite, interfacial zones, etc., [5,17,19].

Despite the fact that the results from deconvolution present me-

chanically distinct phases rather than chemically distinct phases,

they are closely related. Based on the SEM imaging, cement

chemistry and mixture composition, it is assumed that the phase

A in Figure 7 is composed of low stiffness porous phases, the

phase B contains majority of the main hydration products (C-S-

H gels and partly Ca(OH)

2

), the phase C is composed of high

stiffness hydration products (high stiffness C-S-H and partly

Ca(OH)

2

), the phase D contains the remaining non-hydrated clin-

ker, fly ash or quartz filler. Due to unavoidable phase interactions,

the obtained elastic moduli do not exactly represent material con-

stants for pure phases, which is manifested mainly for the stiffest

components, such as the clinker, whose elastic modulus reaches

~130 GPa on a pure clinker sample, [25,29]. However, separa-

tion of the mechanical performance of the individual components

is not possible from the measured response and the influence of

Figure 5 – Example of load-penetration curves

Figure 6 – Load and depth

of penetration versus time

Figure 7 – Experimental and best-estimated

PDF obtained by deconvolution

Table 6 – Elastic modulus and volume

fraction obtained by deconvolution

Matrix

phases

Elastic

modulus

[GPa]

S.d.

[GPa]

Volume

fraction

[%]

A

24.4

8.35

6.3

B

41.3

3.70

48.8

C

54.3

4.07

27.4

D

81.2

13.29

17.5