Basic HTML Version

365

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

W. R. L. da Silva | L. R. Prudencio Jr

|

A. L. de Oliveira

3.1

Determining the coefficient of variation

of the probe penetration test

3.1.1 Description of the experimental program

The tests that were used to determine the coefficient of variation

of the probe penetration test were performed in shotcrete plates

measuring 0.60×0.60×0.15 m (width x length x height) with a com-

position identical to that used on-site. The dosage of the concrete

used in the projection of the plates and in the tunnel is highlighted

in Table 1. The plate mouldings were inclined at an angle of 60° (in

the horizontal plane) and shaped during the projection of the con-

crete in the tunnel. This measure aims not only to represent the

conditions observed on site but also to prevent the incorporation of

the material reflected and the consequent formation of low strength

concrete lenses.

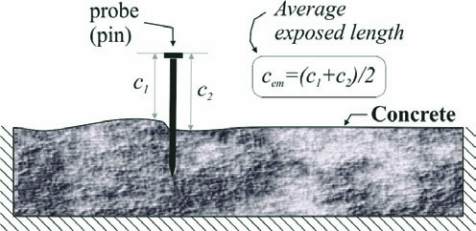

For the probe penetration test, it was initially considered to mea-

sure the inclination angles and exposed lengths of the driven

pins. Nonetheless, due to the lighting conditions of the tunnel and

the high number of tests to be performed, the average length of the

exposed probe was determined by averaging two measurements

of the exposed length using a digital calliper, as shown in Figure 3.

It should also be noted that the increased roughness of the tunnel

finishing, and the surface finish of the concrete plates, are deter-

mining factors for the adoption of the measurement method used

in this study.

The probe penetration test was performed using controlled pro-

pulsion energy (kinetic energy). Such control was required when

observing the results of the early-age tests, which indicated that

the use of maximum propulsion energy resulted in the complete

penetration of the pin in most cases. This initial response is

likely associated with the low level of strength of the shotcrete

in the tunnel.

The reduction in the propulsion energy was obtained by increas-

ing the distance between the capsule where the powder load is

inserted and the pin, as illustrated in Figure 4a,b. The control of

the distance, d

p

=100 mm, from the probe to the powder load was

performed using a metal rod with a diameter similar to the probe

head and a backstop defined by a metal ring welded to the rod

(Figure 4b). This procedure was carried out throughout the experi-

mental program with the objective of reducing errors and, at the

same time, facilitating the test performance, as the operator need

than that specified in the project, i.e., f

ck

= 25.0 MPa.

To perform the probe penetration tests, the Walsywa gun -

DFG 40S Model was used. Furthermore, 22.0 mm cartridges and

55.0×6.35 mm (length × diameter) pins were used. The equipment

used in the test is illustrated in Figure 2. The Walsywa gun was

adopted to replace the Windsor gun because the latter was dif-

ficult to obtain and relatively costly. The Walsywa gun was first

used in Brazil to predict concrete properties, such as compressive

strength, in a study developed by Vieira, [13]. Currently, this meth-

od has been widely employed to investigate possible non-confor-

mities in reinforced concrete structures in studies such as those by

Evangelista, [14], and Pinto & Baggio, [9].

According to the literature, the probe penetration test is charac-

terised by a high variability, [1,2,14]. This variability results from

factors associated with errors caused by both the operator and the

equipment due to the heterogeneous character of concrete. Errors

caused by the operator, who should be duly qualified to perform

the tests, can be considered minimal, and the variability originates

mainly from the factors associated with the equipment, such as

varying the powder charge in the cartridge. The presence of coarse

aggregates in the concrete and the distribution of voids throughout

the mass greatly affect the test results and are considered to be

the main reason for the high variability of the test [2].

As a result of the above-mentioned factors, a greater number of

tests is necessary to detect significant variations in the concrete

strength when comparing, for example, the probe penetration test

with the rebound hammer test. Nevertheless, several published re-

sults, e.g., [15-17], indicate that the coefficient of variation of the

probe penetration test would not be as high, which would reduce

the total number of tests required to obtain reliable results when

investigating the strength of the finished concrete structure.

Because divergences exist, the coefficient of variation of the probe

penetration test was determined with the equipment used in this

study. Note that the determination of the coefficient of variation

of this test was performed prior to the completion of the stages

described earlier in this section.

It is important to mention that the results from the preliminary study,

which were used to determine the coefficient of variation of the

probe penetration test, are required to define the number of tests

that need to be performed in the following steps, namely, in stages

1 and 2. Thus, to facilitate the understanding of the experimental

program, the results of the preliminary steps were presented along

with a description.

Table 1 – Shotcrete mixture composition

used in the tunnel lining

Materials

Shotcrete composition

Cement CP IV 32 RS

3

400 Kg/m

Natural sand

3

720 Kg/m

Stone powder

3

120 Kg/m

Coarse aggregate

4.75/12.5mm

3

980 Kg/m

Accelerating admixture

40 l/m

3

Figure 3 – Reading of the exposed

length of the probe (pin)