Basic HTML Version

366

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

Probe penetration test applied for evaluating shotcrete compressive strength

not worry about measuring the exact distance of the probe in the

trigger pipe every time the test is performed.

A total of ten tests were performed on the same concrete plate at an

age of 28 days. In each test, the powder contained in the cartridge

used in the test was measured, and the coefficient of variation was

determined. To reduce possible errors caused by the operator, all

tests were performed by the same, properly qualified individual. The

results obtained are discussed in the following section.

3.1.1 Results and discussion of results

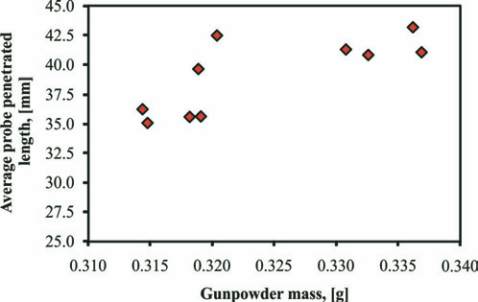

The results of the embedded probe length and the cartridge pow-

der are shown in Figure 5. These values were calculated as the

difference between the average lengths of the pin, which, in this

case, was 54.9 mm, and average measured exposed length, as

depicted in Figure 3. Table 2 lists the values of the average em-

bedded probe length and the average powder obtained based on

the individual values highlighted in Figure 5.

Based on the results in Table 2, a total coefficient of variation

of 8.1% was obtained. The low coefficient of variation is connect-

ed, among other factors, to the small variation in the powder load

contained in the cartridge. Furthermore, the fact that the tests have

been carried out by the same operator and that the mixture of the

shotcrete has been produced with a coarse aggregate with a maxi-

mum dimension of 9.5 mm has also contributed to reducing the

total variability of the test, [1,2]. Due to practical measures that are

connected to the high number of tests to be performed and based

on the low variability of gunpowder, it was decided not to measure

the powder mass over the remaining experimental stages.

The determination the total number of tests n to be performed for

each concrete plate evaluated in stage 2 is based on the relative

maximum error E described in equation (1).

(1)

,

2

2

2

)1 (,2/

E

CV

t n

n

×

=

- a

where CV is the coefficient of variation of the test in percent, E

is the maximum relative error in percent, n is the total number of

tests, and t

a

/2

corresponds to the constant distribution of the t-Stu-

dent [18] test for a significance value of α/2. It should be noted that

the value of α was defined as 5.0%. Furthermore, it is highlighted

that the solution of equation (1) is obtained by an iterative process

because the constant value t

a

/2

is a function of n.

The lower the maximum relative error admitted, the greater the

number of tests that need to be performed. However, factors such

as the cost of conducting the tests, the amount of time working

inside the tunnel, and the equipment costs must be taken into ac-

count to minimise the amount of testing that is performed and,

consequently, the direct and indirect costs related to the execu-

tion. Depending on these variables and in accordance with the

technical team responsible for implementing the tunnel, a maxi-

mum relative error of 10.0% was chosen.

By applying the values of the coefficient of variation of the probe

penetration test, CV = 8.1%, outlined in Table 1 and the maximum

relative error, E

r

= 10.0%, fromequation (1), it was possible to obtain

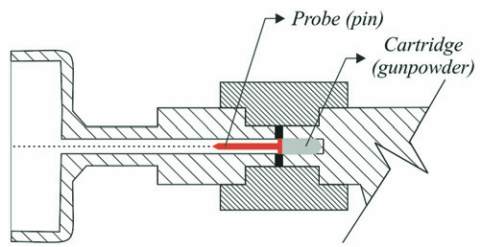

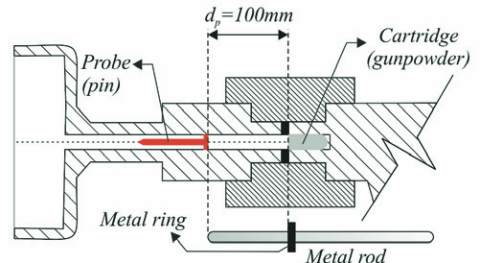

Figure 4 – Propulsion energy (shooting): (a) maximum power and (b) reduced power

A

B

Figure 5 – Individual results of the penetrated

length of pins and the mass of

the gunpowder in the cartridge