Basic HTML Version

368

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

Probe penetration test applied for evaluating shotcrete compressive strength

where s

m

is the average standard deviation s

j

of each of the plates

for different ages, which is calculated by using equation (8); x

m

is

the mean of average values obtained in each of the plates for dif-

ferent ages; and CV

m

corresponds to the coefficient of variation.

(8)

,

1

1

2

å

=

×

=

N

j

j

m

s

N

s

where N is the number of sample groups; N = 4.

3.3

Stage 2: The probe penetration test along

the shotcrete layer of the tunnel

This stage aimed to evaluate whether the strength of the shotcrete

layer along the tunnel would meet the value specified in the proj-

ect. Nevertheless, performing probe penetration tests along the entire

surface of the lining layer would be impractical, mainly due to difficul-

ties in reaching all of the regions corresponding to the tunnel’s vault.

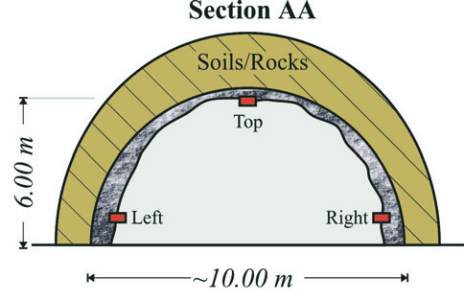

Therefore, three points for each pre-defined cross section were

evaluated. The points where the tests were performed correspond

to the sides and superior regions of the tunnel section, as depicted in

Figure 6. The tests were carried out in the tunnel over a period of 40

to 50 days after the projection of the last 100.0 m of concrete lining.

The tunnel sections were evaluated in different directions because of the

possibility of variation in the concrete compaction as a function of the pro-

jection angle and the distance. In ideal conditions, the concrete should be

projected perpendicularly to the structure. Nonetheless, in stretches such

as the roof of the tunnel, there are technical difficulties that can result in

variation in the projected angle. However, for a single projected mixture,

the experimental results indicate that such variation only affects the con-

crete strength and not the relationshipwith the probe penetration test [20].

Thus, the use of a 60º angle in the projection of the concrete plates used

to define the test’s correlation curve, which is discussed in section 3.1.1,

has no significant influence on the correlation of the test.

In general, the sections were marked every 5.0 m or 10.0 m along

the length of the tunnel. For each region, three tests were performed,

resulting in a total of nine rounds per section. In total, 610 tests were

conducted over the 450m length of the tunnel. More specifically, a

total of 235 tests were conducted in each of the sides and 140 tests

on the top. The reduced number of tests conducted on the top of the

tunnel is due to difficulties encountered in reaching the top of the

tunnel and performing the reading of the exposed length of the pin.

4. Results and discussion of results

4. 1

Stage 1: Determination of the correlation curve

of the probe penetration test

At this stage in the research, two shotcrete plates were tested. The

Figure 6 – Location of the points of the probe

penetration tests in each of the cross

sections measured in the tunnel

Table 3 – Probe penetration test results in the concrete plates

Plate 1

Plate 2

Age

13 days

36 days

13 days

36 days

Probe (pin)

C [mm]

em,

C [mm]

em,

C [mm]

em,

C [mm]

em,

1

34.21

35.05

18.23

19.30*

2

37.64

37.82

20.27

29.67

3

40.05*

33.89

21.82

24.32

4

37.37

36.91

16.59

25.29

5

33.59

32.93

22.65

26.35

6

36.14

35.76

28.68*

27.19

Average, [mm]

35.79

35.39

19.91

26.56

Standard deviation, [mm]

1.83

1.83

2.51

2.05

*Outlier: excluded from the analysis and not considered to compute average and standard deviation values;