Basic HTML Version

369

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 3

W. R. L. da Silva | L. R. Prudencio Jr

|

A. L. de Oliveira

results from the probe penetration test are listed in Table 3. It is im-

portant to mention that the results deemed spurious were removed

from the sample to produce the correlation curve.

The evaluation of the average coefficient of variation of the test, as

measured by the mean values and standard deviations listed in Table

3 as well as by equations (7) and (8), result in a coefficient of varia-

tion CV equal to 7.1%. This value is consistent with the value obtained

in the variability study of the test and is used to determine the number

of tests to be performed at this stage, as stated in section 2.1.1.

The test results of the compressive strength of the samples ex-

tracted from the plates are highlighted in Table 4. It should be not-

ed that the results of this test had to be corrected due to the varia-

tion in the height of the core samples and the possible presence of

micro-cracks caused by excessive vibration during the extraction

of the core samples. Corrections were performed according to the

recommendations presented in [21]. The values of the increased

average strength, which are highlighted in Table 4, were used in

the definition of the correlation curve.

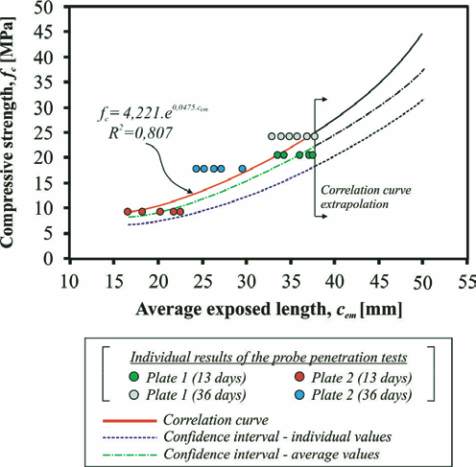

The correlation curve of the probe penetration test, along with a

confidence interval of the individual and average values defined

by equations (3) and (4), is depicted in Figure 7. The lower limit

of the confidence interval outlined in Figure 7 is equivalent to the

concrete characteristic strength curve when a significance level of

5.0% was adopted.

As presented in Figure 7, the correlation curve does not cover in-

tervals over 25.0 MPa. Therefore, if the strength values observed

in the concrete lining of the tunnel are above the results obtained

in the samples, the correlation curve must be extrapolated. How-

ever, because the plates have been moulded during the projection

process, the existence of in situ values similar to those observed in

the concrete plates is probable, which presents evidence that the

concrete lining of the tunnel shows non-conforming results.

The expression of the correlation curve of the probe penetration

test is detailed in equation (9). The correlation coefficient R

2

ob-

tained in the definition of the curve was 0.807. Considering the

variability that is intrinsic of the probe penetration test in addition

to the variability associated with the characteristics of shotcrete,

the correlation coefficient of 0.807 can be considered accept-

able. It is important to note that although this value is acceptable,

complementary studies are required to obtain a better correlation

coefficient among the results. Such studies include, for instance,

increasing the sampling universe, thus enabling a more profound

statistical analyses.

Table 4 – Results of the compressive strength testing of samples extracted from the concrete plates

Plate

Core

sample

Compressive

strength,

[MPa]

h/d

Correction

factor

Corrected

compressive

strength,

[MPa]

Increased

compressive

strength,

[MPa]

Average

increase

compressive

strength,

[MPa]

Age,

[days]

1

1-1

18.3

2.13

1.00

18.3

20.1

20.6

13

2-1

19.2

2.12

1.00

19.2

21.1

13

3-1

20.3

1.87

0.99

20.1

22.1

24.3

36

4-1

25.0

1.58

0.97

24.1

26.5

36

2

1-2

8.7

1.39

0.95

8.2

9.0

9.4

13

2-2

9.2

1.44

0.95

8.8

9.7

13

3-2

15.4

1.42

0.95

14.7

16.1

17.8

36

4-2

18.8

1.37

0.94

17.7

19.5

36

Figure 7 – Correlation curve:

exposed length of the

pin × compressive strength