Basic HTML Version

667

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

P. V. P. SACRAMENTO | M. P. FERREIRA | D. R. C. OLIVEIRA | G. S. S. A. MELO

zation of the behavior of the slab-column connection. They argue

that, as shown in several experimental punching tests, the curva-

ture in the radial direction is concentrated in the region close to

the support, so that concentric cracks in the form of rings are only

observed in this region. In the rest of the slab only radial cracks

are observed (see Figure 9a). Since shear is not transferred in

the tangential direction, the stress state is not affected by such

cracks. In the region of the tangential cracks, part of the shear

may be resisted by aggregate interlock on the surface of cracks

and another part may be supported by dowel effect of the flexural

reinforcement. As the tensile strength of concrete in the tensile

diagonal is reached the tangential cracks (originally caused by

bending of the slab) start to spread towards the column.

Also according to reports from several authors, including Ferreira

[1], compressive strains in the radial direction nearby the ends of

the column, after reaching a certain maximum value at a certain

load level, start to decrease. Just before the punching failure it is

possible to observe tensile strains in this area. This phenomenon

can be explained by the formation of an elbow shaped strut (see

Figure 9b) with a horizontal tensile member as a result of the ad-

vance of the critical shear crack, cutting the compression zone.

The opening of this crack reduces the resistance of the compres-

sion strut because it affects the capacity of transferring shear for-

ces by interlock aggregate and can eventually lead to a punching

failure. Also according Muttoni and Schwartz [33] the thickness of

this crack is proportional to the product ψ∙

d

(see Figure 8). Howe-

ver, the transmission of shear in the critical crack is directly linked

to its roughness, which in turn is a function of maximum aggregate

size. Based on these concepts Muttoni [3] shows that the shear

strength provided by the concrete can be estimated according to

Equation 6

.

(6)

where:

u

1

is the length of a control perimeter

d

/2

away from the faces of the

column (see Figure 7c);

f

c

is the compressive strength of concrete;

ψ

is the rotation of the slab;

d

g0

is a reference diameter of the aggregate admitted as 16 mm;

d

g

is the maximum diameter of the aggregate used in the concrete

of the slab.

The rotation

ψ

of the slab is expressed by the Equation 7.

(7)

where:

r

s

is the distance between the axis of the column and the line of

contraflexure of moments;

r

q

is the distance between the axis of the column and the load line;

r

c

is the radius of the circular column or the equivalent radius of a

rectangular column;

f

ys

is the yield stress of the tensile flexural reinforcement;

E

s

is the modulus of elasticity of the tensile flexural reinforcement;

V

E

is the applied force;

2

s

flex

R

q c

r

V

m

r r

π

= ⋅ ⋅

⋅

−

;

2

1

2

ys

R

ys

c

f

m f d

f

ρ

ρ

⋅

= ⋅

⋅

⋅ −

⋅

.

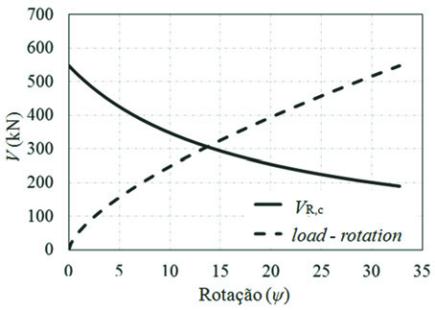

With

V

E

, ψ

and

V

R,c

is

possible to draw a graph with two curves. The

first is a curve that expresses the theoretical load-rotation behavior

of the slab. The second curve expresses the strength reduction of

the slab due to the increase of rotation. The point of intersection of

these two curves express the punching strength of a slab-column

connection. Figure 10 illustrates this graph.

6. Evaluation of theoretical methods

Aiming to evaluate the accuracy of the theoretical methods presen-

ted in the previous sections, results of tests on 74 flat slabs were

taken together in a database. The main criterias for the formation

of this database were the level of reliability of the results, trying to

select results with great acceptance within the scientific community,

and the range of the database related to the parameters that influen-

ce the punching resistance of flat slabs without shear reinforcement.

Were used slabs tested by Elstner and Hognestad [2], Kinunnem

and Nylander [14], Moe [15] Regan [20], Marzouk and Hussein [18],

Tomaszewicz [34] and Hallgren [17]. Table 1 shows the characteris-

tics of the slabs of the database. It should be emphasized that slabs

in this database partially attend the limits of design codes. For exam-

ple, NBR 6118 states that the smallest thickness for a flat slab must

be 160 mm, which does not occur in all the slabs in the database.

However, it is considered that scientifically it is important not to stick

to these limits, since the interest is to understand the phenomenon

as a whole and not just for the most common design situations.

Figure �� � �raphic representation of the punching

strength determination according to CSCT