Basic HTML Version

694

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

Concrete properties produced with recycled coarse aggregates

Alagoas. Both the recycled sand and coarse aggregates were

obtained by the reduction process in a mill of hammers. The fig-

ure 1 shows the composition of the recycled coarse aggregates

from the CDW.

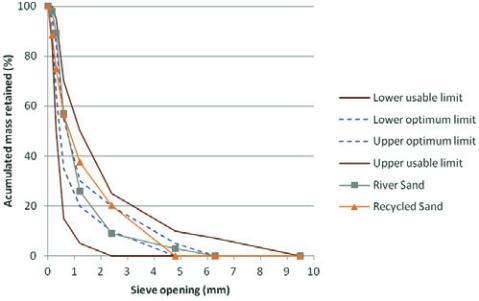

The naturally fine aggregate used was natural river sand, but the

recycled sand aggregate was from the mineral fraction of CDW

obtained in a mill of hammers, sieved in a 4.75 mm sieve. The

properties of the fine aggregates are shown in table 1 and figure 2.

The natural coarse aggregate used was crushed stone of the

maximum of 19 mm in diameter, typically used in the city. There

were two types of recycled coarse aggregates: the first from CDW

(called G1), figure 3a, and the other from the mixture of G1 with the

CW (called G2), figure 3b. Both aggregates were sieved in a 25.4

mm sieve and were predominantly retained in the 4.75 mm sieve.

The specific mass of G2 was defined based on the studies of CAR-

RIJO [10] and ANGLE [11]. In their studies, the specific mass aver-

age of the aggregate particles was formed by mixing particles of

different materials (mortar, rock, ceramic etc.), each one with a

different specific mass.

The amounts of CDW and CW aggregates were calculated by an

equation system formed by the equations 1 and 2 listed below. The

Ta�le � � �ine aggregate properties

Property

River sand

Recycled sand

Standard procedure

Water absorption (%)

1.22

9.34

NBR NM 30 [12]

Density (kg/dm³)

2.68

2.50

NBR 9776 [13]

% organic matter (ppm)

< 300

< 300

NBR NM 49 [14]

% particles with D<0,075 mm

1.00

8.61

NBR NM 46 [15]

Dmax (mm)

4.75

4.75

�

�

NBR 248 [16]

Fineness modulus

2.82

2.78

Grading zone

Usable

Usable

Figure 2 � �ranul�metri� �ur�es �� �ine

aggregates and limits (NBR NM 248:2003)

Figure � � �e����ed aggregate: (a) G1 and (b) G2

A

B