Basic HTML Version

695

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

J. J. L. Tenório | P. C. C. Gomes | C. C. Rodrigues | T. F. F. de Alencar

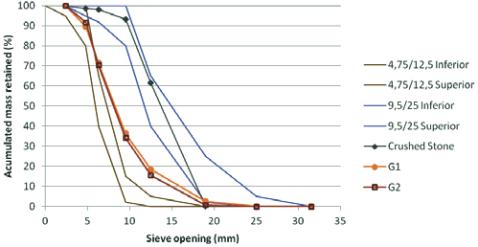

77.26. The coarse aggregate properties are shown in table 2 and

figure 4.

The cement used was composed by Portland CPII-F-32. A 3rd

generation superplasticizer based on an ether-modified carboxylic

chain was used to used to assure an appropriate consistency to

the concrete. The water used was the water available in the labora-

tory’s water system.

2.2 Mix design

The composition parameters of the concrete taken as independent

variables in this study were:

n

Effective water-cement ratios: 0.67, 0.50 and 0.40 were de-

termined fixing the used in agreement with NBR 6118 [20] for

structural concretes;

n

The specific mass of the recycled coarse aggregate: 2.08 kg/

dm³ for G1 and 2.27 kg/dm³ for G2;

n

Fine aggregate: natural sand and recycled fine aggregate

of CDW.

The compositions obtained for the combination of the param-

eters and reference mixtures are shown in Table 3. The water

was fixed at 20% of 1 m3 (200 kg) and cement dosage at 300,

400 and 500 kg/m3. The method of mixing did not follow any

commonly used method. The amount of coarse aggregate was

fixed at 40% for all the mixtures; this percentage was deter-

mined previous to the normal mixture with a mortar content of

50%. First, the form of mixing of the reference concrete was

determined in volume and only the mixtures of RAC were calcu-

lated. This was done so that the difference between the specific

mass of the natural and recycled aggregates did not lead the

production of different concrete volumes.

2.3 Production

According to FERREIRA [21] the reducing of the effective w/c ra-

tio of the mix can to be overcome if the water absorbed by the

recycled aggregates is compensated or by extra water added to

the mix or by the recycled aggregates pre-saturated added to the

first is a formulation that relates the specific mass of each aggre-

gate and the second is a relation by mixing two materials.

(1)

γ

γ

%M γ

%M

G2

CWA

CWA

G1

G1

(2)

1

%M

%M

CWA

G1

In the equations 1 and 2, %MG1 is G1’s coarse aggregate percent-

age in mass; γG1 is the specific mass of G1’s coarse aggregate;

%MCWA is CW’s coarse aggregate percentage in mass; γCWA is

the specific mass of CW’s coarse aggregate and γG2 is the spe-

cific mass of the mixture or, in other words, G2’s coarse aggregate.

The resolution of the system of equations above with the adequate

values of specific mass resulted in %MG1 = 22.74 and %MCWA =

Figure 4 � �ranul�metri� �ur�es �� ��arse

aggregates and limits (NBR NM 248:2003)

Ta��e 2 � �oarse aggregate properties

Property

(1)

Brita

G1

G2

Standard procedure

Water absorption (%)

0.49

8.41

5.37

NBR NM 53 [17]

NBR NM 53 [17]

Specific mass (kg/dm³)

2.62

2.08

(2)

2.27

Index of particle shape

2.60

2.30

2.20

NBR 7809 [18]

(3)

% particles with D< 0.075 mm

0.33

0.75

0.45

NBR NM 46 [15]

�

�

Dmáx (mm)

19.0

19.0

19.0

NBR 248 [16]

Fineness modulus

6.86

5.76

5.85

Grading zone

9.5/25

None

None

(1) - Crushed stone coarse aggregate; (2) - The intended value was 2.25 kg/m³ (which was used in Equation 1).

The experimentally obtained value was 2.27 kg/m³; (3) - using NBR 7219 [19].