Basic HTML Version

711

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

E. RIZZATTI | H. R. ROMAN

|

G. MOHAMAD | E.Y. NAKANISHI

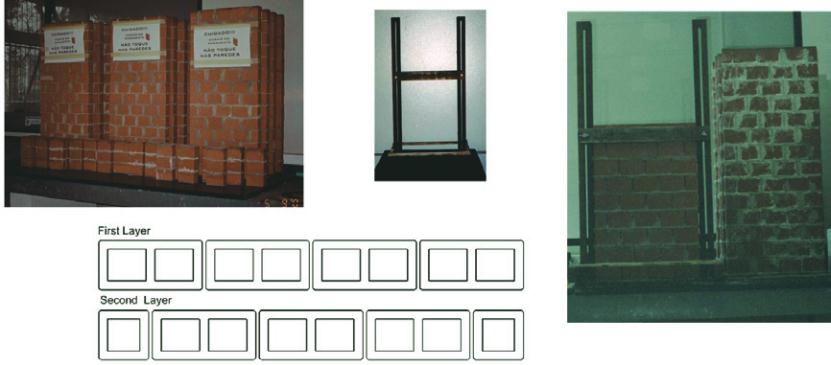

standards as shown in Figure 12. Bedding mortar used in the ex-

perimental tests followed the recommendation of BSI-5628-1 [10],

where the proportions of cement:lime:sand by volume were 1:1:6

(Mortar – I) and 1:0.5:4 (Mortar - II). Mortars recommended in the

British standards were used because they presented minimum

Figur��������r��i�g��i�i��������r��r�����

mechanical characteristics for each type of proportioning. The wa-

ter/cement relation was adjusted to achieve a fixed consistency

of 270 mm ± 10 mm when measured on a flow table. The bed-

ding mortar was prepared using a mixer with a vertical axis. For

each mortar, six cylindrical specimen 5 cm in diameter and 10 cm

in height were moulded for 28-day compression testing following

procedures in NBR 13279 [13]. The specimens were cured in a

laboratory environment for 28 days to reproduce the conditions of

prisms and walls.

Ta�le � � Ma�� unit� Portland Cement� Hydrated lime and �and u�ed in t�e mortar�

Material

Portland cement CP II F-32

Hydrated lime CH III

Natural Sand

3

Mass unit (kg/dm )

1,12

0,64

1,33

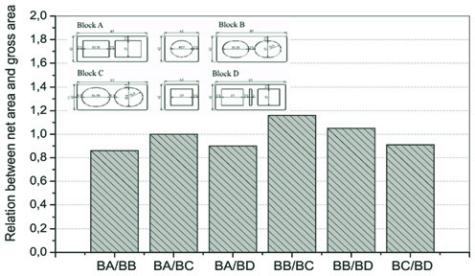

Figure �� � �elations�i� bet�een net

and gross area for different blocks

Figur��������ri�������������������r��u����r�����u�i�g����������������������r������