Basic HTML Version

712

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 5

Mechanical behavior analysis of small-scale modeling of ceramic block masonry structures –

Geometries effect

The granulometric distribution of sand used in the experimental

tests followed the recommendations of BS 1200 [14]. Portland ce-

ments CP II- F-32 and CH-III-type hydrated lime were used. Deter-

mination of the unitary mass of the cement and the lime followed

the procedures described by NBR 7251 [15]. Table 04 shows the

values of the unit masses of cement, lime and sand.

The geometries of the blocks had the following characteristics:

1 – Block type A –a model with two rectangular hollows similar to

the format of concrete block;

2 – Block types B and C – both types with two circular hollows.

The block type B maintains the same thickness for the face

shell and cross webs, resulting in a higher net area. For block

type C the net area was maintained equal to the block type A;

3 – Block type D –a model with two rectangular hollows. The in-

ternal cross webs thickness is double the thickness of the face

shell plus that of the mortar joint. This causes a meeting on

the vertical joints of the mortar.

The relationships between the different net areas of the blocks are

presented in Figure 13, where it can be observed that the relation-

ship between the net and gross area of blocks A and C (BA/BC)

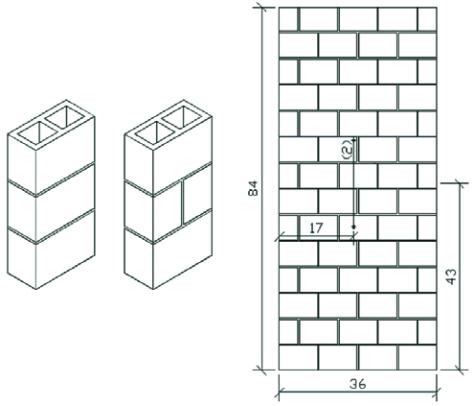

Figure �� � �risms and �alls for e�aluation

of the influence of geometry on masonry

(dimensions in cm)

are 1.0, that is, both blocks have the same relationship between

the net and gross area.

The walls were built with an apparatus that ensured that the blocks

were level, aligned and vertical in each row, following the recom-

mendation of NBR 8949 [16]. Table 14 presents the first and sec-

ond rows with the apparatus for execution of the wall. For the dif-

ferent types of blocks, five prisms with and without vertical joint

and three walls were built for each type of mortar, as shown in

Figure 15. Table 05 presents the descriptions of the different tests

of blocks, prisms and walls. The designation PA1 indicate the

prisms with block type A and mortar I while the designation PPB2

indicates a masonry wall built with block B and mortar type II. The

designation code is as follows: A, B, C, D = block, P = prism; PP =

masonry wall; 1 = mortar type 1:1:6; and 2 = mortar type 1:0.5:4.

Due to the difficulties of implementing tensile tests on the blocks, it was

decided to obtain the tensile strengths of the blocks indirectly by dia-

metric compression as shown in American Standard ASTMC1006-84

[17]. The cylindrical steel bars required for the tests were between 1/8

and 1/12 of the height of the sample and had lengths greater than their

widths. The bars were aligned with the central crossing web in each

block. The load applied at a rate of 0.33 MPa/min. The tensile strength

was then determined by using Equation 01.

(1)

f

t

=

H.L.

P.2

Where:

f

t

= tensile strength by diametric compression (MPa); P =

applied load (kN); L = length (mm); and H = height of the sample.

Values of the tensile strength determined by diametric compres-

sion are presented in Table 06, together with a depiction of the

test device.

Sixteen blocks of each geometry were randomly selected for the

compression tests. Blocks were prepared for testing by the follow-

ing procedure:

– the top and bottom of the blocks were covered with a mixture

of 70% cement paste plus 30% sand retained in the 0.15 mm

sieve to avoid cracking caused by shrinkage;

– after the capping of the top and bottom of the blocks the speci-

mens were immersed in water for 24 hours;

– excess water was removed with a dry rag before the tests

Compression tests were performed by incrementally applying the

load at a rate of 0.5 MPa/second. The compressive strength of the

gross area gives a standard strength for a constant area that is

independent of geometry effects.

Ta�le � � Denomina�ions o� �locks, mor�ar, prisms and walls

Block

Type A (BA)

Type B (BB)

Type C (BC)

Type D (BD)

Prism

Mortar I

PA1

PB1

PC1

PD1

Mortar II

PA2

PB2

PC2

PD2

Wall

Mortar I

PPA1

PPB1

PPC1

PPD1

Mortar II

PPA2

PPB2

PPC2

PPD2