Basic HTML Version

764

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 6

Pull Off test to evaluate the compressive strength of concrete: an alternative to Brazilian standard techniques

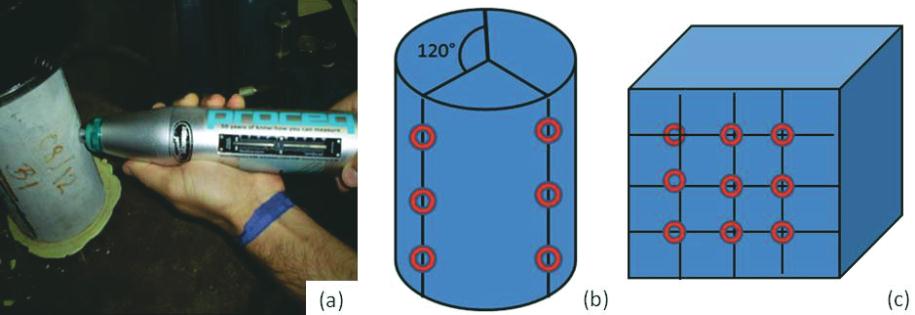

Figure 7 – a) Rebound hammer; b e c) Measurement points in the specimens

The simple compression test on cylindrical specimens was per-

formed following the procedures proposed in NBR 5739 [1] [Fig-

ure 8 (a)]. The simple compression test on prismatic specimens

was performed according to BS 12390-3 [3] [Figure 8 (b)]. For both

tests was adopted the loading speed of 0.4 MPa/s.

3.7 Pull Off test

The Pull Off test applied to concrete is not standardized in Bra-

zil. This study adopted the recommendations of BS 1881: Part

207 [13]. In this method, the traction is axially transmitted to

a metallic disc bonded beforehand into the concrete surface.

After a period of time enough to cure the epoxy resin used for

bonding the discs, a tensile force is applied to the disc using a

portable mechanical system [Figure 3 (a)]. The gradual increase

in tension can be directly observed on a scale (MPa), and the

maximum tension is logged, as soon as the pullout of concrete

happens. The equipment used for the tests was the Dyna Z 16E

Proceq [Figure 3 (b)].

For implementing the Pull Off test concrete slabs of 55 cm x 55

cm x 20 cm molded in the laboratory with the same concrete used

in the specimens of the resistance test were used. Nine readings

were performed on each slab. The amount of readings in each

slab was defined by recommendations of BS 1881: Part 207 [13].

Another factor in the sizing of the slabs is the recommendation

from the standard that discs should be set at a minimum of two

diameters to each other and positioned at a distance of a diameter

from the edges of the element to be tested. The material of the

discs used in the assay is aluminum and its dimensions are 25 mm

high and 50 mm in diameter.

The test was conducted with a surface cut of 5 mm deep according

to the dimension of the metallic disc. The execution of the cutting

was done to avoid the influence of the surface conditions of the

concrete, as in the case of carbonated surfaces.

Figure 8 – Compressive strength test (a) cylindrical specimens and (b) cubic specimens