Basic HTML Version

765

IBRACON Structures and Materials Journal • 2012 • vol. 5 • nº 6

E. PEREIRA | M. H. F. de MEDEIROS

Before starting up the bonding of metallic discs in the concrete

surface, the surfaces were prepared to obtain good adhesion.

This procedure is adopted mainly for removal of the cement

paste on the concrete surface and to make the aggregate ap-

parent. A caution was taken so that the place of bonding was

plain enough to ensure that the adhesive is present in the en-

tire contact surface between the disc and the concrete, ensur-

ing that the strength is applied uniformly throughout the area

of bonding. To regularize this site was used a sander with fine

sandpaper. The bonding was performed with a thin layer of ad-

hesive and the surplus concentrated around the disc was re-

moved still fresh, thus ensuring that the rupture surface had

the area of the disc. An epoxy resin was used as adhesive with

curing time of 24 hours.

4. Results and discussion

Initially, the test results obtained in the experimental program were

treated statistically in order to eliminate spurious values

,

which

could compromise the validity of analyzes.

For the rebound hammer tests nine readings on each specimen

were determined, being considered a valid reading when at least

five individual values did not differ from average by more than

10%. According to NBR 7584 [11], the values outside the range

were discarded and the average was recalculated only with valid

values

.

This procedure was performed on five specimens of the

same concrete. At the end of the preliminary treatment, the final

result was calculated as the simple average of the final values ob-

tained from valid samples.

To prismatic and cylindrical specimens tested in compression and

in ultrasound tests, it was considered the average of the six speci-

mens. The Pull Off test is not standardized in Brazil and therefore

in this study were used the recommendations of BS 1881 Part 207

[13]. Nine points in each specimen were tested, being considered

valid if at least six individual values did not differ from the mean ±

one standard deviation. All specimens were within this limit. The

Table 3 – Gathered data in non-destructive tests and compressive

strength test using cylindrical and cubic specimens

Concrete

Concrete

Cubic specimens (15 x 15 x 15cm)

Rebound hammer

Rebound hammer

Ultrasound test

Ultrasound test

Pull Off

Pull Off

Compressive strength

Compressive strength

(MPa)

(MPa)

(MPa)

(MPa)

(MPa)

(MPa)

(MPa)

(MPa)

Low cement content

31

4511.2

1.91

30.32

Intermediate cement content

38

4635.2

2.8

37.83

High cement content

40

4702.5

3.08

44.63

Cylindrical specimens (Ø15 x 30cm)

Low cement content

37

4570.5

1.91

30.00

Intermediate cement content

36

4613.8

2.8

38.87

High cement content

46

4641.5

3.08

45.73

pullout strength was obtained with the average of the valid values

after the initial treatment.

The average values of compressive strength, ultrasound test, Pull

Off test and rebound hammer after pretreatment are shown in

Table 3.

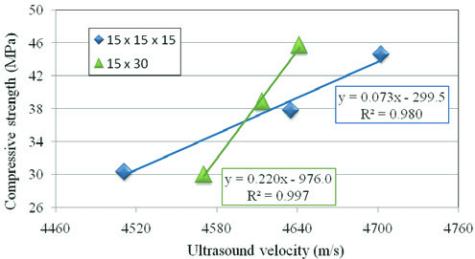

With the data in Table 3 were created graphs to demonstrate

the correlation between the non-destructive tests and the

compressive strength of cylindrical and cubic specimens for

the three concrete mixtures studied. Figure 9 refers to the

correlation between the compressive strength and the re-

bound number.

In Brazil, the rebound hammer is the most popular non-destructive

test, but some researchers question the effectiveness of the meth-

od to accurately estimate the concrete strength. Rebound hammer

data show a direct relationship between the compressive strength

results and the rebound number. Moreover, there is a weak cor-

Figure 9 – Correlation between rebound

hammer and compressive strength test

in cylindrical and cubic specimens